Laser Jailer

Active Laser Guarding Safety System

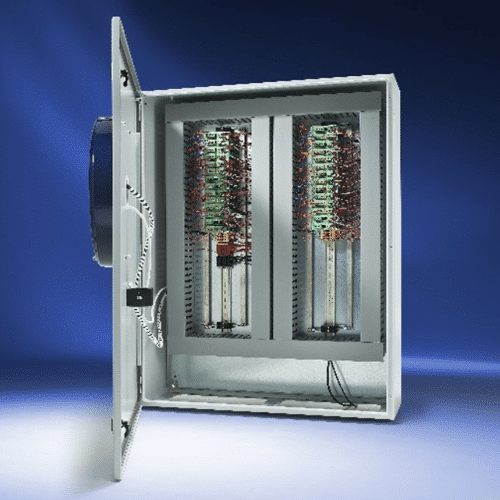

The Laser Jailer combines an inherently fail-safe laser detection technique and Lasermet’s proven laser Interlock® control system technology to create an active laser guarding system conforming to Machinery Directive Standard EN 13849-1.

- Active and Passive Laser Enclosures

- Lightweight, modular, scalable

- Retrofit to existing rooms and enclosures

- Rapid turnkey solution

- Conforms to laser safety standards EN/IEC 60825-1 and ANSI Z136.1

Description

Laser Jailer® Active Laser Safety System

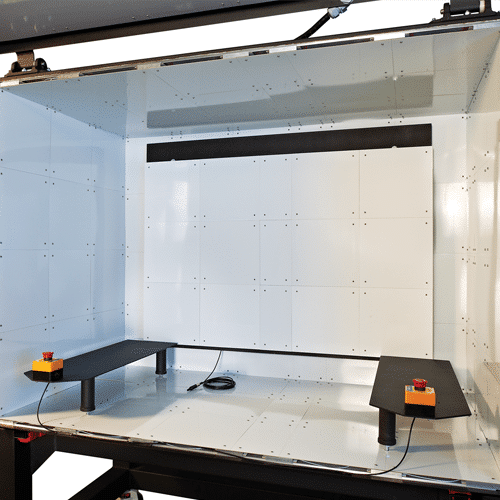

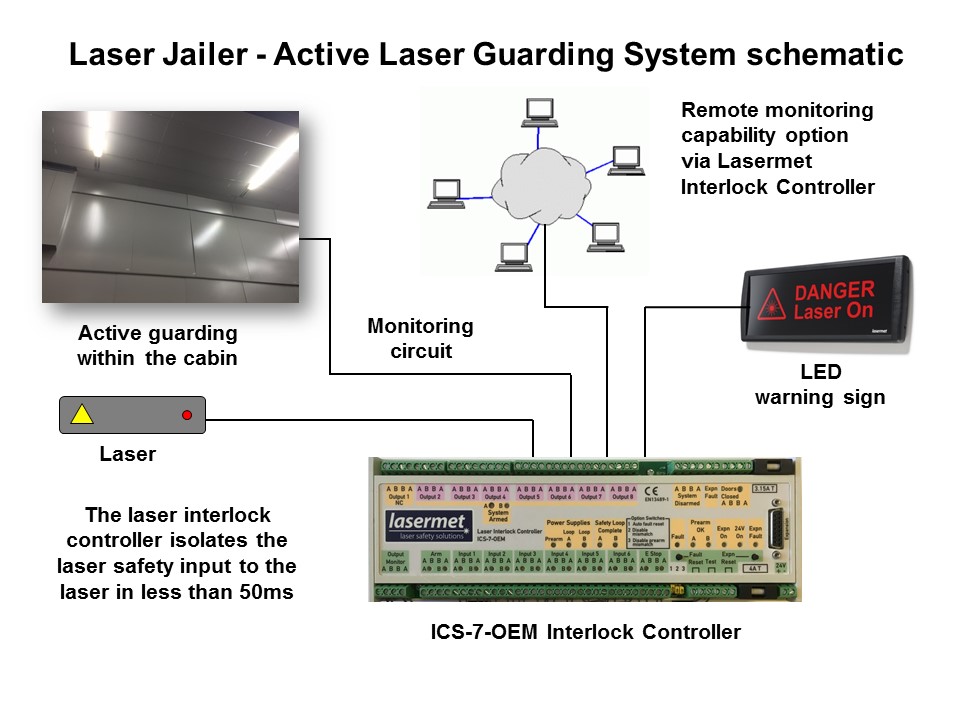

The Laser Jailer Active Guarding System by Lasermet is designed to contain a high powered laser beam in a laser enclosure. The complete Laser Jailer System comprises of an outer passive laser safety enclosure which is lined throughout with laser beam detector tiles. These active guarding panels, which also act as a laser shield, are connected to the laser safety Interlock® System. Any stray laser beam impacting one of the tiles will isolate the laser in less than 50ms.

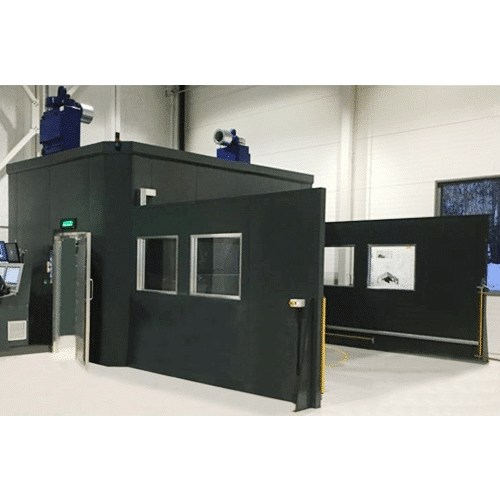

Virtually any size of laser enclosure can be fitted with the Laser Jailer Active Guarding System – from small enclosures to full room-sized laser shelters containing robot welding machines. The fully commissioned laser cabin will then act as an effective laser barrier to confine the laser beam within the laser cabin.

ACTIVE DETECTOR PANELS

Each Active Guarding Panel (or detector tile) contains a laser detector circuit which is connected to the laser Interlock® System.

If a high power laser is directed at any of the tiles within the laser cell, it changes the properties of the circuit which is detected by the Interlock® Controller to turn the laser off. Due to the extremely high power of some lasers, the tiles have been designed to be easily replaced once they have been struck by a high energy laser beam. These sacrificial detector sheets can be folded and overlapped to fit into corners or to fit around equipment. The tiles have a simple connector at each end to facilitate easy repair and replacement.

RETROFIT TO EXISTING ENCLOSURES OR CELLS

Being a modular active laser protection system, the Laser Jailer system can be retrofitted to an existing enclosure. Passive laser safety systems cannot contain high power lasers that have a small beam.

The Lasermet active laser safety control system design is lightweight, adaptable, repeatable and maintainable, and uses fail-safe technology.

COST EFFECTIVE ACTIVE LASER GUARDING

The laser guard design – using active technology – is cost effective because it can reduce the requirement for some of the strength and weight of some of the surrounding infrastructure.

The Laser Jailer® Active Laser Guarding System ensures the laser is made safe if its beam is directed at the laser enclosure walls or ceiling.

BENEFITS OF ACTIVE LASER GUARDING

- Inherent Fail-safe technology

- Conforms to the design and laser safety standards

- Versatile, modular, scalable, lightweight

- Provides maximum protection

- Standard or custom-built design

- Easy to maintain

- Rapid availability

- Reduces building infrastructure

REMOTE MONITORING

This schematic shows how the active safety system can be integrated with Lasermet’s Interlock® System which can have the option of being monitored via the internet.

CONFORMANCE TO LASER SAFETY STANDARDS

The system is certified for and conforms with:

- BS EN IEC 60825-4 Safety of Laser Products

- BS EN ISO 13849-1:2008 Safety of Machinery – Safety-related parts of control systems

- Machinery Directive

- Low Voltage Directive

- Electromagnetic Compatibility Directive

Applications for Active Laser Guarding

The Laser Jailer is an effective laser containment system ideal for housing laser applications and activities such as laser drilling, laser welding, laser ablation and laser cutting. Industrial applications where the Laser Jailer can be used include the aerospace industry that uses laser machining, laser trimming and the laser repair of turbines. It is also a safety consideration to contain lasers in applications that use laser additive manufacturing of complex parts and additive welding.

Lasers, and the subsequent laser safety equipment and training, are now used in the energy and nuclear industry where they are used for welding pump components for nuclear power plants and are even used for underwater laser welding and under-water laser cutting.

Even in the dismantling of nuclear power plants they can be are used for concrete scabbling and to cut thick concrete slabs.

LASER DANGERS TO BE CONSIDERED

Lasermet’s active laser guarding system is designed to prevent death by laser and to prevent injury by laser. This high speed active laser safety control system also prevents destruction by laser, that is, of the surrounding infrastructure. This includes preventing damage from laser beams to the building and its services. The Laser Jailer is much more than a simple beam blocking barrier and, which ever guard system the customer decides upon – either active or passive laser blocking, Lasermet can design and manufacture the complete bespoke laser cabin.

The fast response of the active laser guard system is achieved by sensing the laser impacting on the active laser wall within the laser room. If a stray laser beam impacts on one of the tiles, the Interlock® will isolate the laser safety input in less than 50ms. The laser will then be turned off – the precise shut-off time being dependent of the laser machine in use.

The Laser Jailer® is effective against all laser wavelengths and can be used in material processing, for example, in the automotive industry in applications such as laser welding, and in aerospace and renewables for laser hardening, laser profiling, laser surface cleaning, laser dressing and laser machining.

In the medical and healthcare industries, the machining of parts using lasers can be carried out within and active or passive laser safety enclosures depending on the power of the laser being used.

PASSIVE vs ACTIVE GUARDING

Conventional laser cabins have to be robust enough to withstand accidental exposure to the laser – acting as a laser shield. Passive laser guards must withstand laser radiation for the foreseeable maximum exposure time. Typically they will need to confine a laser beam to between 10s and 10,000s depending on the situation.

High beam power (>1kW) in small beam diameters will cut through steel and even firebricks in a relatively short period of time. For very high beam powers (>5kW), even large beam diameters have the potential to break through concrete. In these circumstances passive guards must be far enough removed from the laser aperture to ensure they can withstand the beams power density. This is not always practical.

An active laser guard allows you to have a much smaller enclosure, as the required containment time is 50ms.

Ordering Options

To specify the Laser Jailer® Active Laser Guarding System you require, the following items must be addressed.

- Specification of the laser

- Intended use of the laser

- Dimensions and specification of the laser safety enclosure – a large laser enclosure may need estimated measurements for quotation purposes

- Identification of relevant safety interlocks -doors, switches, maglocks.

Lasermet are happy to assist if you would like to know more about the system and we can arrange for a site visit if you are unsure of the level of safety you require.

Additional information

| Active Guarding Panel Size | 500 x 630 mm |

|---|---|

| Standards | BS EN IEC 60825-4 Safety of Laser Products |

| Patents | The Laser Jailer® Active Laser Guard System has the following patents : US Patent No. 8 416 820 |