Laser Castle

Passive Laser Safety Cabin

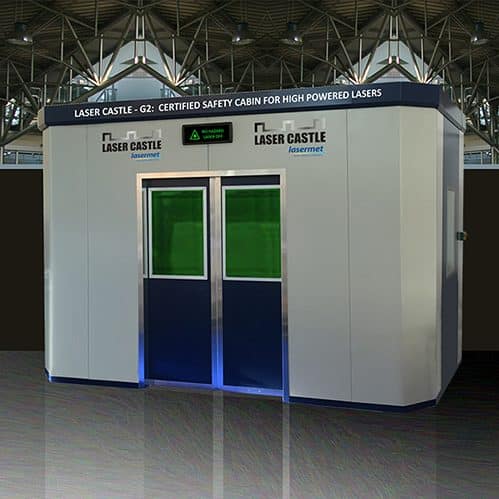

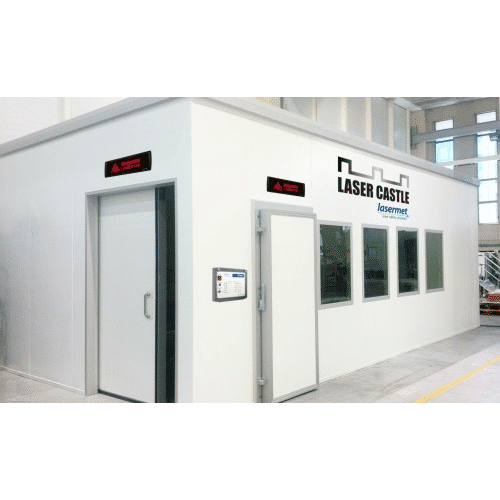

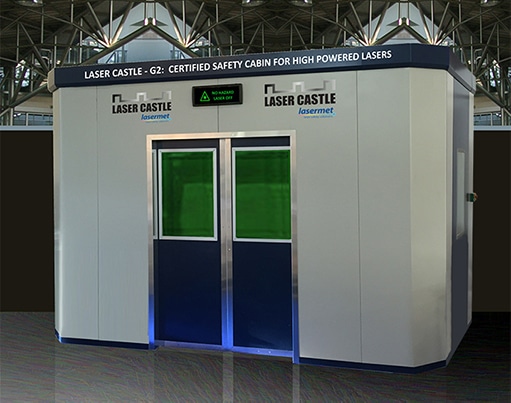

Lasermet’s Laser Castle® laser safety cabins protect personnel from the dangers of high powered laser beams by absorbing the laser power in the specially designed walls and roof. These modular, Class 1, room-sized enclosures are tested and certified to international laser safety standards and can be rapidly designed, built and installed by Lasermet.

- Rapid-build modular laser safety cabins

- Passive Class 1 Enclosures for Class 4 lasers

- CE Certified to EN IEC 60825-4 Safety of Laser Products Part 4 – Laser Guards

Description

The Laser Castle is a Passive Guarding Class 1 Laser Safety Cabin suitable for high-power Class 4 lasers.

The system comprises of panels constructed from laser blocking material and certified to the Laser Safety Standard EN IEC 60825-4. The panels are connected together (including an optional roof) to form the enclosure.

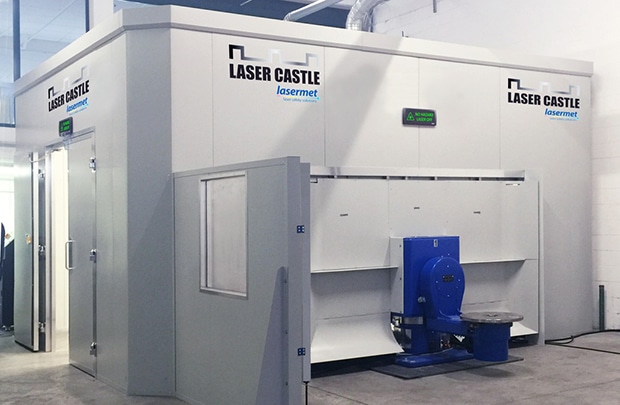

Laser Castle cabins are ideal for laser welding robots that need to be contained as they typically use 4kW lasers in their operations. Higher powered lasers can also be accommodated, for example, 10kW or 20kW.

Laser Castle Components

DOORS

Access into the enclosure is provided by doors made of our special laser blocking panels. Several standard door options are available including sliding doors, personnel doors, double doors, roll-up doors, and guillotine doors. Laser Castle doors are designed to provide maximum access in a minimum space.

WINDOWS

Viewing windows provide added value to many laser processes where operators need to see inside the enclosure. Windows can optionally be fitted to doors or walls of the Laser Castle. Standard window options range from passive laser blocking filter windows to active interlocked windows.

ROOF AND CUSTOM DESIGNS

Laser Castle cabins can come with roof or no roof, depening on your needs. Other custom cut-outs, bump-outs, and turntables can be specified at ordering. If you are unsure of the specifications or measurements you need, Lasermet can send out one of our qualified technicians for a site visit.

ELECTRICAL SYSTEM & LIGHTING

The electrical wiring is run in containment channels inside the enclosure. Lighting packages are recommended for Laser Castles with a roof. The Laser Castle and laser safety Interlock® system is designed, manufactured, and installed by Lasermet.

HD CCTV MONITORING SYSTEM

A CCTV system may be installed with the enclosure. Either one or two remotely controlled cameras operate inside the enclosure transmitting video to the video monitor(s) outside the enclosure. When two cameras are installed, the video monitors can be controlled to show the view from either camera using a joystick controller.

FUME EXTRACTION SYSTEMS

Provisions can be made for fume extraction systems, making this a cost effective and extremely easy method of enclosing the laser system to comply with international laser safety standards.

Laser Castle with Laser Interlock® System

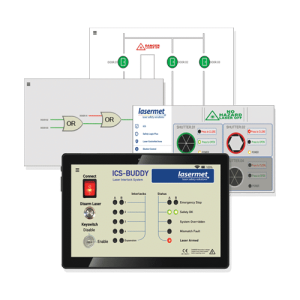

Though Passive Laser Castles can provide sufficient laser blocking for some systems, Lasermet recommends ordering a Laser Castle with a Laser Interlock® System. Lasermet’s Interlock® Control System includes LED Warning Signs, Interlock® Controllers, interlock switches, door maglocks, and more.

-

-

-

-

LED Ultra Signs£363.00 – £428.34

LED Ultra Signs£363.00 – £428.34

ILLUMINATED WARNING SIGN

A dual message, dual colour, LED laser warning sign above the door indicates the status of the laser as it is controlled by the Interlock® controller. The LED sign, including the laser warning triangle, reads “Danger Laser On” illuminated in red when the laser is powered on, and reads “No Hazard Laser Off” illuminated in green when the laser is off.

Active Enclosures with Laser Jailer®

Passive Laser Castle cabins can be upgraded to an Active Guarding Laser Enclosure with the Laser Jailer® Active Laser Guarding System.

The patented Laser Jailer® modular system has active detector panels covering the internal walls and roof of the cabin to detect high-powered laser beam strikes. Lasermet’s fail-safe technology isolates the laser safety input in less than 50ms in the event of a stray laser strike.

Laser Castle Installations

The Laser Castle can be fully custom designed and built to suit your needs.

Being a lightweight, modular design, the enclosure can be dismantled, moved to another location, and be re-assembled very quickly. The standard sized panels also enable the enclosure size to be changed, made larger or smaller, easily. This is an ideal, flexible, lightweight solution for rapidly changing environments.

Compliance and Safety Standards

PEL RATINGS

The PEL ratings for the Passive Laser Castle panels are listed below.

| Panel Thickness | Irradiated Area | PEL (T3) 10S | PEL (T2) 100S |

| 50mm | 4 mm² | 150 MW/m² | 87 MW/m² |

| 2000 mm² | 3.1 MW/m² | 1.7 MW/m² | |

| 100mm | 4 mm² | 310 MW/m² | 170 MW/m² |

| 2000 mm² | 5.1 MW/m² | 3.0 MW/m² |

SPECIFICATION TO THE LASER SAFETY STANDARDS ANSI Z136.1 AND IEC 60825-1

To meet the laser safety requirements of ANSI Z136.1 and IEC 60825-1, the enclosure requires a safety Interlock® Control System including appropriate warning signs – both of which are designed and manufactured by Lasermet.

COMPLIANCE TO EN ISO 13849-1

Lasermet’s ICS-9 and ICS-7-OEM Interlock® Control System meet Performance Level e (PL ‘e’) of ISO 13849-1 and is ideal for compliance to the required laser safety standards.

Control of Substances Hazardous to Health

COSHH Information

FIRE

Fire can be easily extinguished in the early stages if quickly tackled with a water, CO2, dry powder or BCF extinguisher.

SMOKE AND FUMES

Burning panels give off carbon monoxide and styrene gas. The amount given off is less than that emitted by wood and other traditional construction materials in comparative tests. The smoke hazard of burning panels is similar to that of any other construction, decorating or packaging material.

CLEANING & MAINTENANCE OF PANELS

Panels may be washed down with fresh water from a hose or a bucket. Water may be heated to 60°C. A solution of fresh water and non-aggressive detergent may be used to remove heavy deposits, followed by a fresh water rinse.

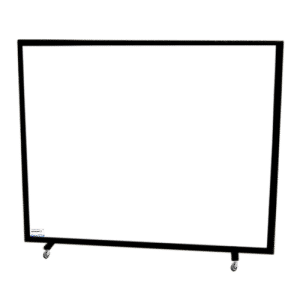

CE Certified Laser Blocking Partitions

We also supply CE certified laser blocking partitions with or without doors, for dividing one laser lab into two or more sections. These semi-permanent partitions are cost effective and extremely quick to install, without the mess and fuss of building a brick or plasterboard wall. As such they offer an alternative to traditional methods of room division, and can also be easily undone at a later date if required. Alternatively they can be left as a permanent installation.

All laser safety partitions are tested and certified to EN 60825-4.

Additional information

| Laser Safety Compliance | The Laser Castle® laser enclosure (including its laser interlock system) complies with the following: |

|---|