When it comes to laser safety in the EU and international markets, IEC 60825-1 and its harmonized counterpart EN 60825-1 set the standard. One of the key requirements under these regulations is the proper use of laser warning labels—not just for hazard identification, but for legal and technical compliance.

This article outlines what manufacturers, integrators, and system designers need to know about laser classification labels under EN / IEC 60825-1, including required label content, placement, and durability considerations.

Standard Labels according to EN IEC 60825-1

The EN IEC 60825-1 standard lays out a few kinds of laser warning labels that you should have on your laser product.

WARNING TRIANGLES

The laser warning triangle symbol is a yellow triangle with a black border containing a black pictogram of a laser beam (starburst). This symbol is an international standard laser warning symbol, often used in conjunction with other labels.

Required for:

Warning Triangle symbols are required on all lasers above Class 1.

| Class 1 | Class 2 | Class 3R | Class 3B | Class 4 |

| Optional | ✓ | ✓ | ✓ | ✓ |

APERTURE LABELS

A laser aperture label is a safety warning label marking the opening or exit point of a laser device. Its purpose is to provide information and warnings to individuals who may come into contact with the laser, especially those who are responsible for operating, maintaining, or servicing the laser equipment.

Warning Triangles are often used interchangeably with Aperture Labels if a symbol-based label is preferred over a text-based label.

Placement:

Aperture labels must be placed on or near the laser aperture. If there are multiple apertures, each aperture must have its own label.

It should be clearly visible during normal operation – not obscured by doors, covers, or accessories when the product is in use. And it must be oriented upright (not sideways or upside-down).

Required for:

These are required on all Class 3R, Class 3B and Class 4 lasers. Most Class 2 lasers require aperture labels with some exemptions.

| Class 1 | Class 2 | Class 3R | Class 3B | Class 4 |

| Optional | ✓ | ✓ | ✓ | ✓ |

CLASSIFICATION LABELS

Laser classes are a standardized system used to classify lasers based on their potential hazards to human eyes and skin. A laser classification label typically includes the laser’s class and signal word such as “Danger” (Class 3B and 4) or “Caution” (Class 2, 2M, 3R), a hazard statement such as “Avoid direct eye exposure”, and may reference the standard it is classified to.

Placement:

Label should be visible during normal operation and on the exterior of the product, and readily accessible but doesn’t need to be near the aperture or warning label.

Required for:

All laser classes are required to have a classification label. If your laser product contains a laser which is Class 1 even when all housings have been stripped away then it may use a simplified classification label.

| Class 1 | Class 2 | Class 3R | Class 3B | Class 4 |

| ✓ | ✓ | ✓ | ✓ | ✓ |

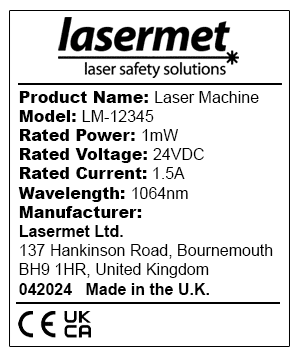

PRODUCT INFORMATION LABELS

A product information label provides valuable information on the manufacturer and specification of the laser product. When used in conjunction with classification labels these need only contain the following:

- Manufacturer’s name and address

- Model number / Serial number

- Date of manufacture

- Maximum output power or energy*

- Pulse duration (if appropriate)*

- Wavelength(s)*

- Number and publication date of standard to which the product is classified*

*if not already included in the classification label

Many designs of product information labels are possible since there is no specific format or layout indicated in the standard. Where space allows, product information and classification labels can go on one label.

Placement:

Product information labels should be located on the exterior of the product and readily accessible, but doesn’t need to be near the aperture or warning label.

Required for:

These are required for all laser products.

| Class 1 | Class 2 | Class 3R | Class 3B | Class 4 |

| ✓ | ✓ | ✓ | ✓ | ✓ |

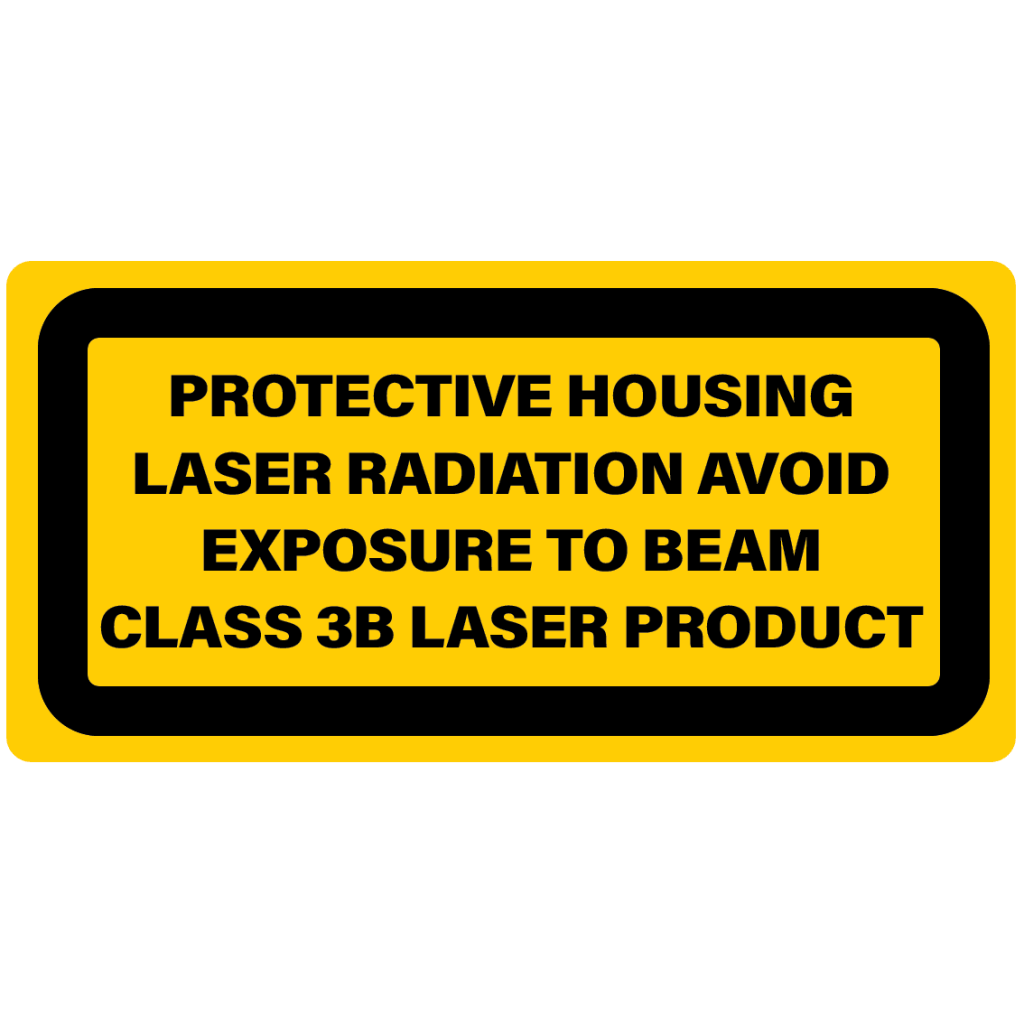

PROTECTIVE HOUSING LABELS

A protective housing label, often referred to as a “protective enclosure label” or “safety housing label,” is a warning label or marking that is affixed to or near protective enclosures or housings surrounding equipment or machinery. These are required on all panels or connections which when removed, opened or displaced will give access to radiation in excess of Class 1.

The class of this label is determined by the class of the laser radiation accessible once the panel is opened. For example, a panel on a Class 1 laser product, which when removed gives access to Class 3B laser radiation will require a Protective Housing Class 3B label.

Placement:

Protective housing labels are placed on internal protective housing or enclosures that enclose the laser or laser source.

Required for:

Protective housing labels are required for higher class embedded lasers of Class 3B or Class 4. If the product is Class 1 with an embedded Class 3B laser, then it will require a protective housing label.

The following table refers to the embedded laser class and not the overall laser product classification.

| Class 1 | Class 2 | Class 3R | Class 3B | Class 4 |

| x | x | x | ✓ | ✓ |

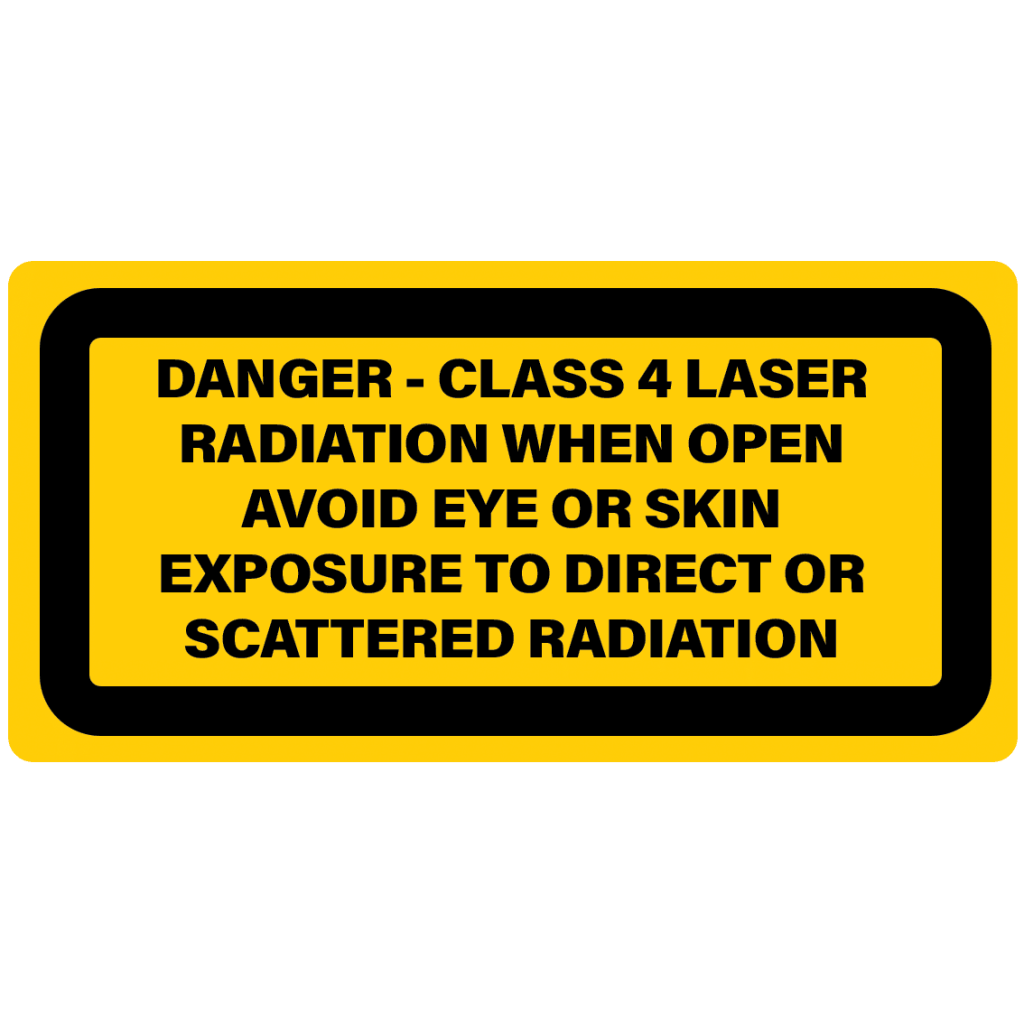

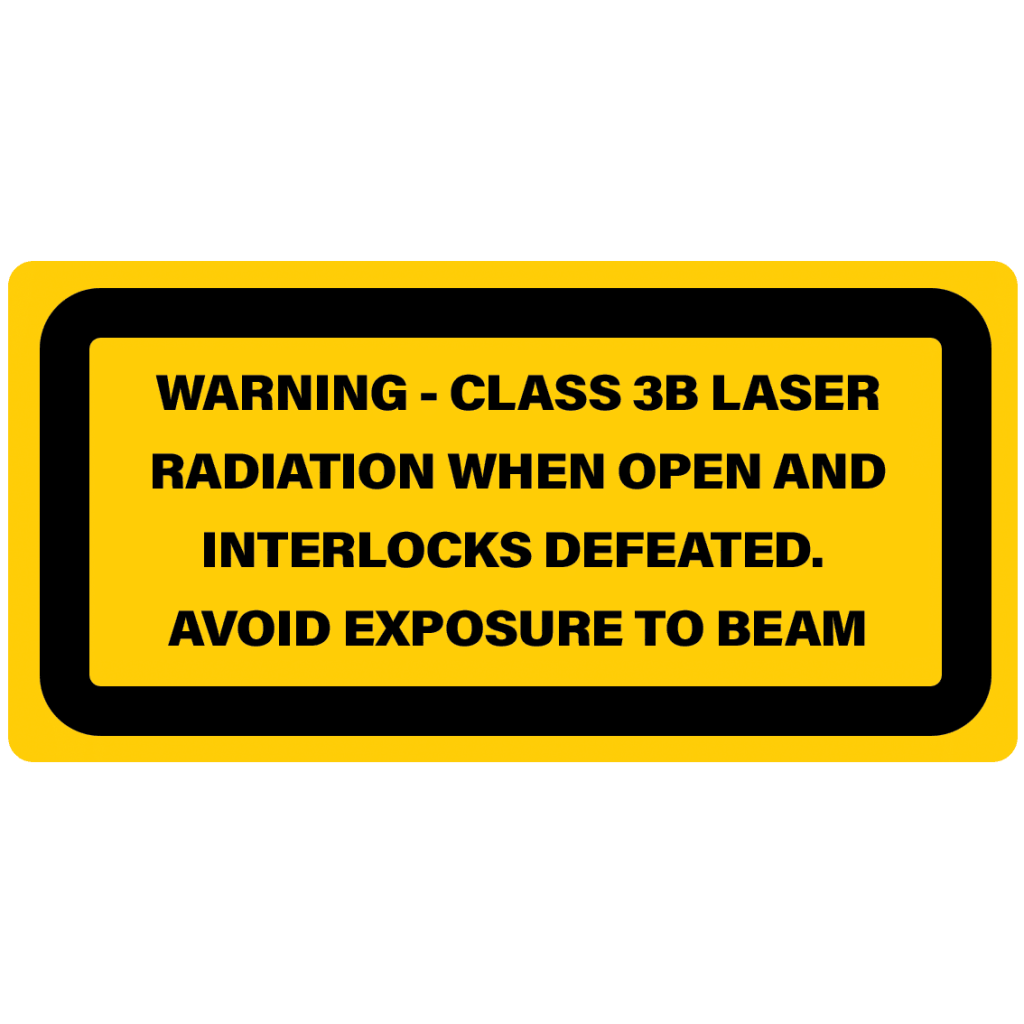

INTERLOCKED HOUSING LABELS

Interlocked Housing labels are required on all interlocked panels which will give access to radiation in excess of Class 1 when opened and the interlock is overridden.

The class of this label is determined by the class of the laser radiation accessed once the panel is opened and the interlock overridden. For example, an interlocked panel on a Class 1 laser product, which when opened and the interlock overridden gives access to Class 4 laser radiation will require an Interlocked Housing Class 4 label.

In this case, interlock only refers to interlocks on access panels or, any interlock that prevents the product from operating when open access panels are open. Any other interlocks are not considered.

Placement:

Interlock labels must be visible both prior to and during opening or removal of the housing. The label should be fixed near the opening and must be visible prior to and during interlock override.

Required for:

Interlocked housing labels are required for laser products with embedded Class 3B or Class 4 lasers. And only when there are interlocked access panels, housing, or enclosures present.

The following table refers to the embedded laser class and not the overall laser product classification.

| Class 1 | Class 2 | Class 3R | Class 3B | Class 4 |

| x | x | x | ✓ | ✓ |

“INVISIBLE” OR “VISIBLE AND INVISIBLE” RADIATION WARNINGS

In addition to the above, there are also specific considerations to the wording of labels when the laser radiation is visible, invisible, or both.

Where the laser radiation is invisible, the ‘invisible radiation’ versions of Classification, Protective Housing and Interlocked Housing labels should be used. Where the laser radiation is both visible and invisible, the ‘visible and invisible’ versions of Classification, Protective Housing and Interlocked Housing labels should be used.

MATERIAL REQUIREMENTS

Though the EN / IEC 60825-1 standard does not state any specific material requirements for labels, it is an accepted rule that all labels should be durable, permanent, and legible.

Durability

The label must be permanent, clearly legible, and resistant to environmental conditions expected in the laser product’s operating environment such as heat, abrasion, chemicals, UV, etc..

Permanence

Labels must not peel, fade, or become unreadable over the life of the product under normal conditions of use.

Labels must adhere securely to the product surface and not fall off during normal use.

Legiblility

High contrast between text, symbols, and background must be maintained.

Where applicable, the correct colouring, wording, symbols and layout as defined in the European, International or US standards must be used.

In summary, laser products must adhere to strict labeling requirements outlined in EN / IEC 60825-1 to ensure user safety and regulatory compliance.

Key labels include classification labels, which indicate the laser class and associated warnings, and product information labels, which provide manufacturer details and product identification. Protective housing and interlocked housing labels are required for higher-class lasers (Class 3B and Class 4) with protective enclosures or interlocked access panels. Aperture labels are mandatory for Class 3R, 3B, and 4 lasers to warn users of potential exposure risks. Simplified labeling applies to Class 1 lasers, with fewer requirements for labeling compared to higher classes.

Understanding these label types and their requirements is crucial for ensuring both safety and compliance with international standards.

Quick Guide to Labelling Requirements according to Laser Class

| Label | Class 1 | Class 2 | Class 3R | Class 3B | Class 4 |

| Warning Triangle | Optional | ✓ | ✓ | ✓ | ✓ |

| Aperture Label | Optional | ✓ | ✓ | ✓ | ✓ |

| Classification Label | ✓ | ✓ | ✓ | ✓ | ✓ |

| Product Information Label | ✓ | ✓ | ✓ | ✓ | ✓ |

| Protective Housing Label | x | x | x | ✓ | ✓ |

| Interlocked Housing Label (if present) | x | x | x | ✓ | ✓ |

Check out our online shop for a wide selection of laser safety labels compliant to international standards.

Disclaimer:

This article is intended for informational purposes only. While every effort has been made to ensure the accuracy of the content based on the IEC 60825-1 standard and related resources, we make no representations or warranties, express or implied, regarding the completeness, accuracy, or applicability of the information provided. This content does not constitute legal or regulatory advice. Readers are advised to consult the relevant standards documentation and seek professional guidance to ensure full compliance with applicable regulatory requirements. We disclaim any liability for decisions made or actions taken based on the information contained herein.