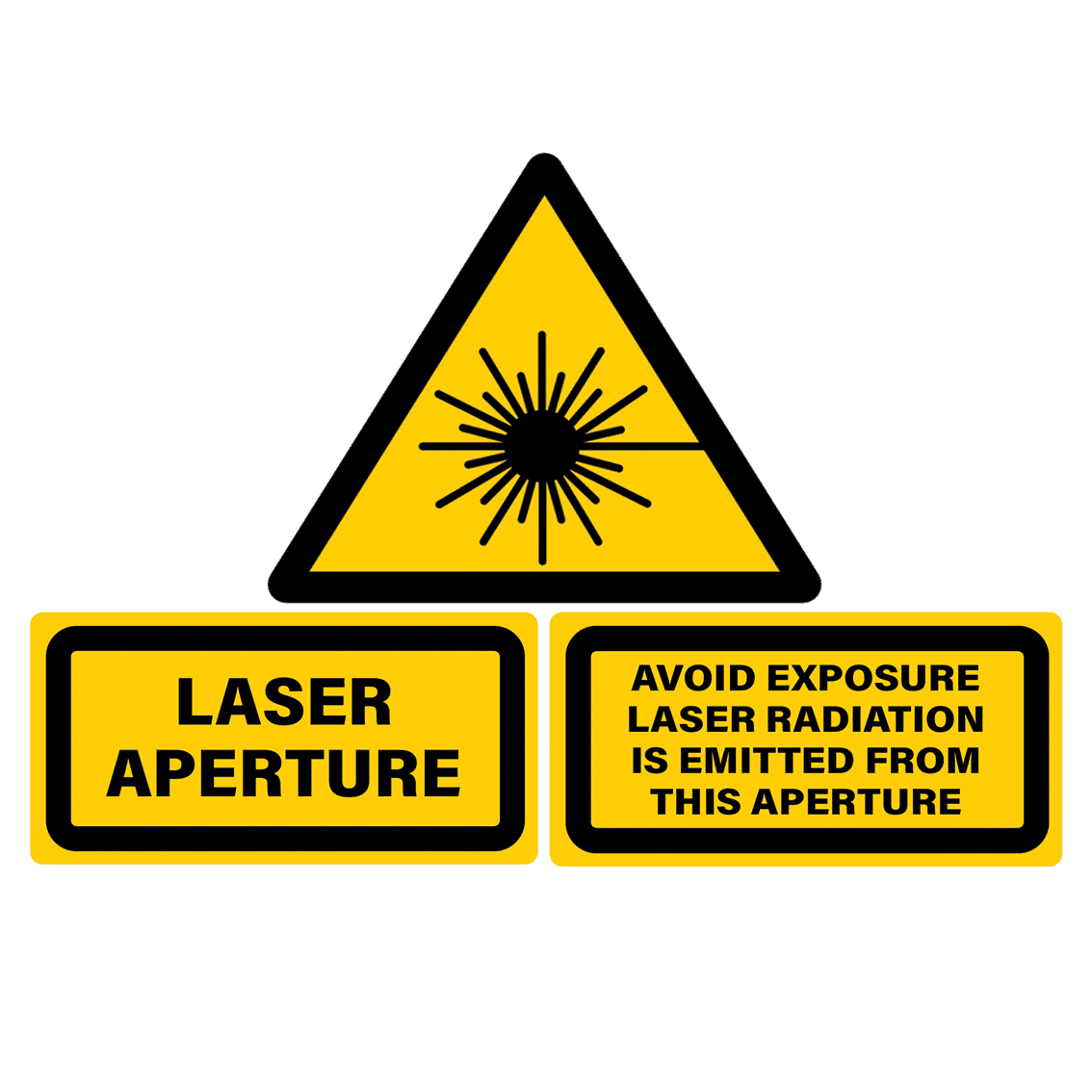

Laser Aperture Label

£1.60 – £9.58

A laser aperture label is a safety warning label or marking placed on or near the opening or exit point (aperture) of a laser device.

The purpose of this label is to provide information and warnings to individuals who may come into contact with the laser, especially those who are responsible for operating, maintaining, or servicing the laser equipment. Laser aperture labels typically contain critical information related to laser safety and usage.

Description

Aperture Labels for Laser Products

LOCATION

The laser aperture is typically located at the front or output end of the laser device. It is where the laser beam exits the laser system and propagates into the surrounding environment.

SHAPE AND SIZE

The aperture’s shape and size can vary depending on the type and design of the laser system. It may be circular, rectangular, or another geometric shape. The size of the aperture can determine the diameter or cross-sectional area of the laser beam.

LABEL STANDARDS

Laser safety labels and warning signs are commonly placed near the aperture to provide essential safety information to individuals who may come into contact with the laser system.

APPLICATIONS

The laser aperture’s design and function can vary based on the specific application of the laser system. For example, in laser cutting and welding systems, the aperture may be integrated with optics to focus the laser beam for material processing.

LASER CLASSIFICATION

Information regarding the laser’s classification, such as Class 1, Class 2, Class 3A, Class 3B, or Class 4, is often indicated near the laser aperture. This classification provides guidance on the laser’s safety and potential hazards.

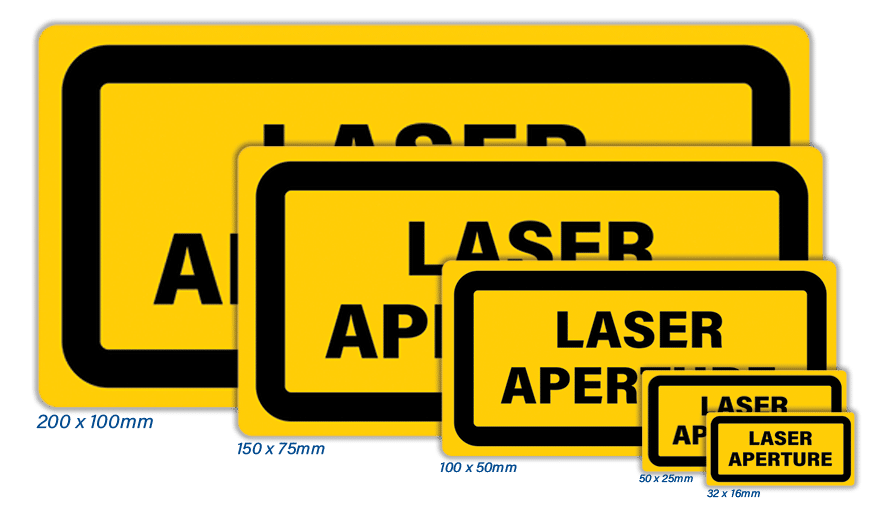

Ordering Options

The labels come in five different sizes.

- 200 x 100 mm

- 150 x 75 mm

- 100 x 50 mm

- 50 x 25 mm

- 32 x 16 mm

Additional information

| Weight | N/A |

|---|---|

| Labels | AP-100X50, AP-150X75, AP-200X100, AP-32X16, AP-50X25, FDA-AP-20X10, FDA-AP-32X16, FDA-AP-50X25 |