What is a laser safety interlock system?

An interlock system is a safety mechanism designed to prevent access to hazardous areas or control potentially dangerous operations unless certain predefined conditions are met.

Interlock systems link the state of one device or component to another, effectively creating a chain of conditions. If one condition isn’t satisfied, the system blocks a particular action (e.g., opening a door, activating a laser).

To maintain compliance to industry standards and ensure safety, many laser operations rely on interlock systems. It protects users, enforces protocols, and is often legally mandated by regulatory bodies like OSHA, ANSI, IEC, and CDRH.

Key Characteristics of Interlock Systems

FAIL-SAFE DESIGN

Defaults to a safe state if there’s a power failure or fault.

LOGIC-BASED

Uses either hardwired logic (electro-mechanical) or software-based control.

ACCESS CONTROL

Prevents physical access to hazardous zones (e.g., laser enclosures).

STATUS FEEDBACK

Reports operational readiness or error states to control systems.

How a Standard Interlock System Works

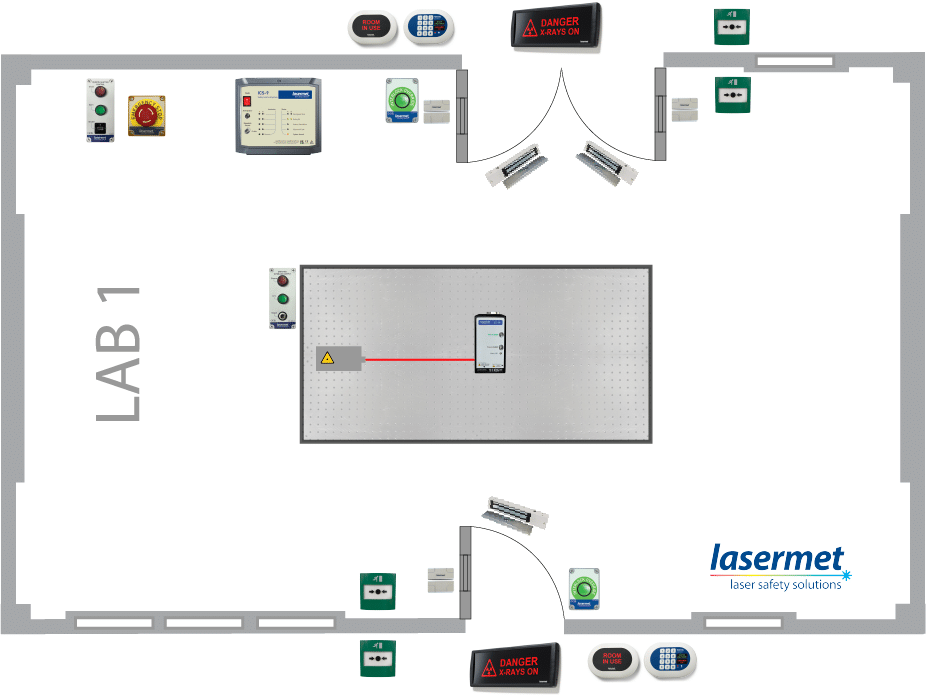

Above is an example of a standard laser interlock system installed in a lab. The lab has two entry points, a double door and a single door, and an optical table set-up with a laser. Warning signs with dual messages “No Hazard Laser Off” and “Danger Laser On” are strategically placed at the entry points. Lasermet’s interlock system provides a comprehensive solution to safety with interlocked doors, tables, emergency stops, and override procedures in place.

In a Class 4 laser lab, the Lasermet interlock system can:

- Automatically disable laser output when the door is opened.

- Require door closure and key switch activation before enabling the laser.

- Integrate with emergency stops and warning signs.

- Override the door to allow entry without disabling the laser output.

- Monitor and control the status of laser beam shutters on an optical table.

DID YOU KNOW?

Lasermet owns the registered trademark for Interlock® in the UK, a powerful marker of industry credibility and innovation, and we’ve held it strong since 2015.

Laser Interlock® Systems for Operating Theatres

The Department of Health document entitled ‘DB2008: Guidance on the safe use of lasers, intense light source systems and LEDs in medical, surgical, dental and aesthetic practices’ states that (within the hierarchy for controlling safety under the heading for Equipment/Engineering), Control measures will include the device interlocks, room interlocks, warning lights, barriers and laser-proof blinds etc.

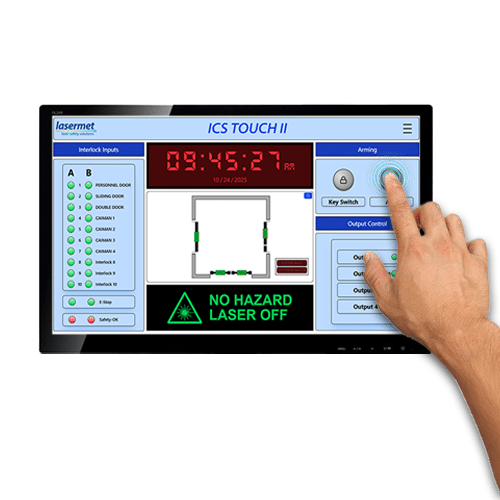

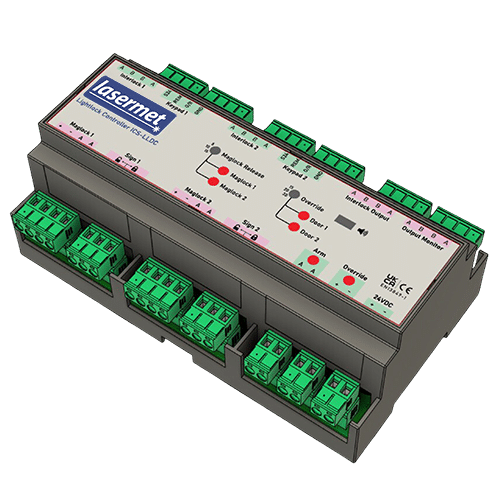

The ideal solution for Interlock® control for operating theatres is the ICS-TOUCH Interlock® Controller.

Interlocks in Laser Systems: A Brief History

1960s–1970s

EARLY BEGINNINGS

The invention of the laser in 1960 marked a significant technological breakthrough, but the early systems were experimental and lacked formal safety protocols. As lasers became more powerful and widespread in research institutions and industry, the need for systematic safety controls became apparent.

By the late 1960s and early 1970s, rudimentary interlocks began appearing. These early systems were primarily mechanical or electromechanical, using door switches or manual key-lock systems to disable laser emission when entry points were open or unauthorized personnel were present. There were no industry-wide safety codes as protection measures were reactive and varied widely between institutions.

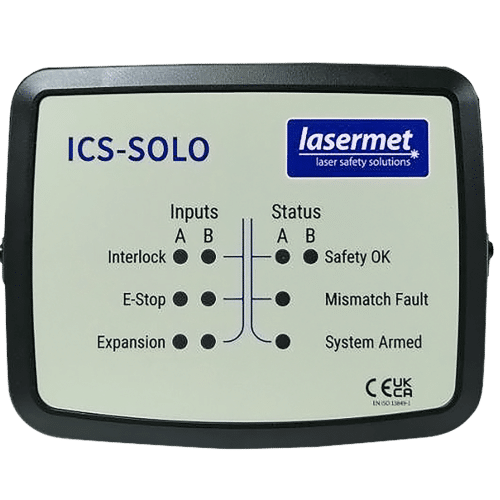

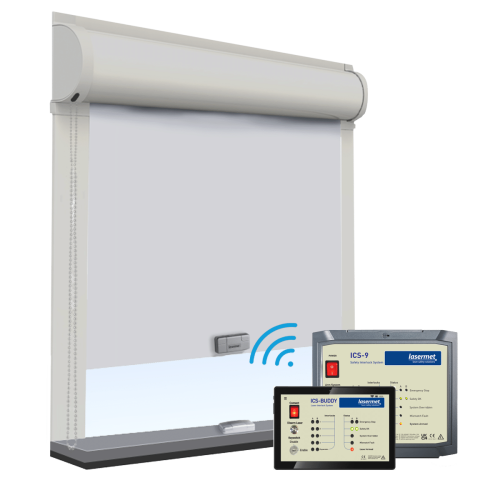

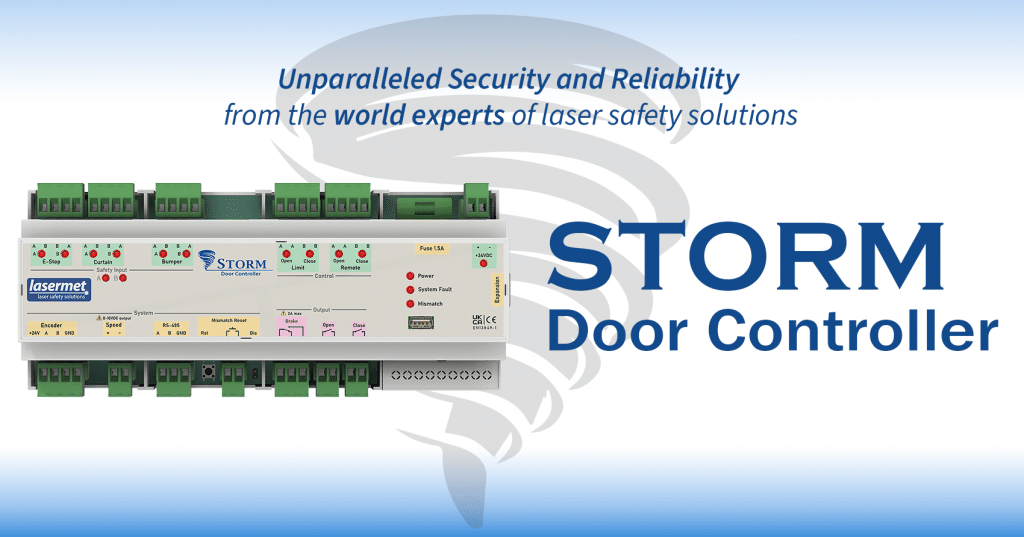

Products in Laser Safety Interlock Systems

Related Articles about Interlocks

Building lasting partnerships and continuing to set the standard in laser safety worldwide