Fraunhofer CLA choose Laser Castle

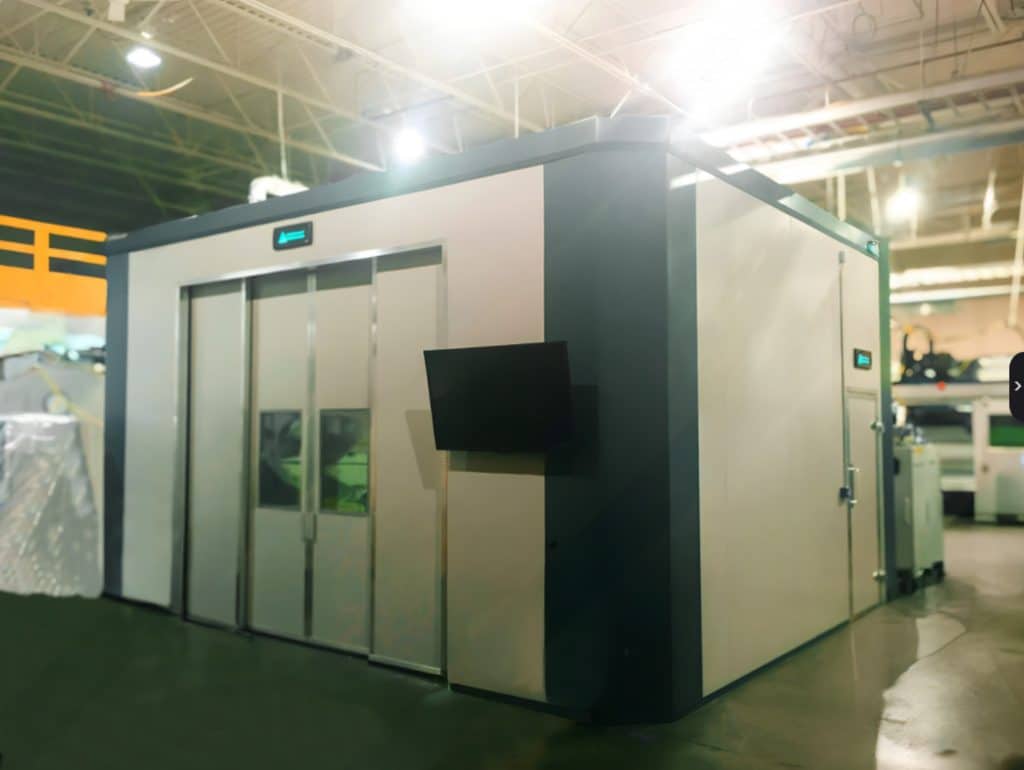

Lasermet recently installed its Laser Castle laser safety cabin at Fraunhofer CLA, the Center for Laser Applications, in Plymouth, Michigan USA. The cabin, which measure 22ft wide, 18ft deep and 12ft tall, (6.6 x 5.5. x 3.6m) enables the facility to accommodate substantial high powered laser machines and related equipment including the ability to house laser welding robots.

Fraunhofer is Europe’s largest application-oriented research organisation with locations throughout the world and Fraunhofer CLA has been operating in the US since 1994 developing new laser applications for a wide range of industrial customers. With its extensive expertise in laser materials processing and a state-of-the-art facility, the Fraunhofer USA CLA team helps to develop best process solutions including laser welding, laser cutting/drilling,laser cladding, and laser heat treatment. Fraunhofer facilities include Robotic and CNC work cells with fiber, disk diode and CO2 lasers up to 16kW and state-of-the-art Metallographic Lab.

The laser safety cabin’s main double-doors open to 10ft(3m) wide and are 10ft(3m) high to accommodate large pieces of equipment. The cabin is certified as laser safe (as required by the laser safety standards within IEC 60825-1 and ANSI Z136.1), and is interlocked with a fully dual-channel interlock control system. Fitted with high definition CCTV and an HD monitor, an additional interlocked access door and dual-message, dual-colour LED Laser warning signs, the Laser Castle provides the complete solution.

Active Laser Guarding “Laser Jailer”

As lasers up to 16kW are used, the only fail-safe way to ensure the safety of personnel outside the cabin is to shut down the laser is an inadvertent laser strike occurs. This is achieved by covering the inside of the cabin with active laser guarding panels which are electrically connected to the interlock controller. These panels are constantly monitored by the interlock and if any of these are struck by the laser, the controller isolates the laser safety input within 50ms, shutting down the laser virtually immediately and preventing the escape of the beam into the surrounding area.

In addition, to the passive and active guarding provided by the cabin, the manual doors have two active Guarding Filter Windows (called “Glaser Jailer”) and these are also linked to the laser interlocked controller (ICS-6) in the same way as the rest of the active laser guarding system. They work in the same way. If the windows are struck, the controller switches off the laser virtually immediately.

Fraunhofer CLA works in close co-operation with the Fraunhofer Institute for Material and Beam Technology (IWS) in Dresden Germany, one of Europe’s leading research institutes for laser material processing.

The installation of the Laser Castle at Fraunhofer CLA in Michigan exemplifies the highest standards in laser safety and engineering excellence. Designed to support high-power laser operations, including robotic welding and other industrial laser applications, the cabin integrates both passive and active laser safety technologies. With dual-channel interlocks, active guarding panels (Laser Jailer), and intelligent monitoring systems, it provides a robust and failsafe environment for laser processing. This setup not only ensures the protection of personnel but also enables Fraunhofer CLA to carry out advanced laser research and development with confidence. As a key part of the Fraunhofer global network, the facility demonstrates a strong commitment to innovation, safety, and collaboration in the field of laser materials processing.