Laser Enclosures Installed Across the World

Lasermet provide a comprehensive installation service for all our laser safety products. This ranges from a simple installation of a laser blocking curtain, right up to installing complex multi-function Interlock® systems and assembly of room-sized Class 1 laser enclosures.

Lasermet design, manufacture, install, and commission laser safety systems for lasers anywhere in the world. The Lasermet Solution is designed to our customer’s needs, no matter how complex the system required. Lasermet provide turnkey solutions to all your laser safety needs.

All of our installers are qualified electricians with extensive experience in laser safety installations and a multitude of practical skills which are essential for providing a high quality installation.

We manufacture our products and provide these services, including installation, in-house. We employ our own installation team and technicians and never use contractors. This means that our installers are highly experienced with our equipment and are committed to achieving a top quality result.

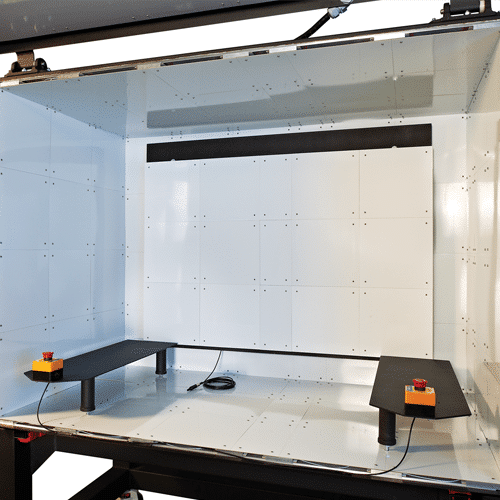

Lasermet have installed thousands of laser safety products such as laser blocking curtains, screens and roller blinds in numerous institutions, hospitals, universities, research establishments and manufacturing facilities worldwide since 1987.

Lasermet design, manufacture, install, and commission laser safety systems for lasers anywhere in the world.

Laser Safety Interlock Systems

To maintain compliance to industry standards and ensure safety, many laser operations rely on interlock systems in addition to passive guarding laser cabins or enclosures. An interlock system is non-negotiable in safety-critical environments. It protects users, enforces protocols, and is often legally mandated by regulatory bodies like OSHA, ANSI, IEC, and CDRH — but what exactly is an interlock system?

An interlock system is a safety mechanism designed to prevent access to hazardous areas or control potentially dangerous operations unless certain predefined conditions are met. Not limited to just laser systems, interlocks are widely used in industrial, medical, and scientific environments to ensure personnel safety and equipment integrity.

Interlock systems link the state of one device or component to another, effectively creating a chain of conditions. If one condition isn’t satisfied, the system blocks a particular action (e.g., opening a door, activating a laser).

Key Characteristics of Interlock Systems

FAIL-SAFE DESIGN

Defaults to a safe state if there’s a power failure or fault.

LOGIC-BASED

Uses either hardwired logic (electro-mechanical) or software-based control.

ACCESS CONTROL

Prevents physical access to hazardous zones (e.g., laser enclosures).

STATUS FEEDBACK

Reports operational readiness or error states to control systems.

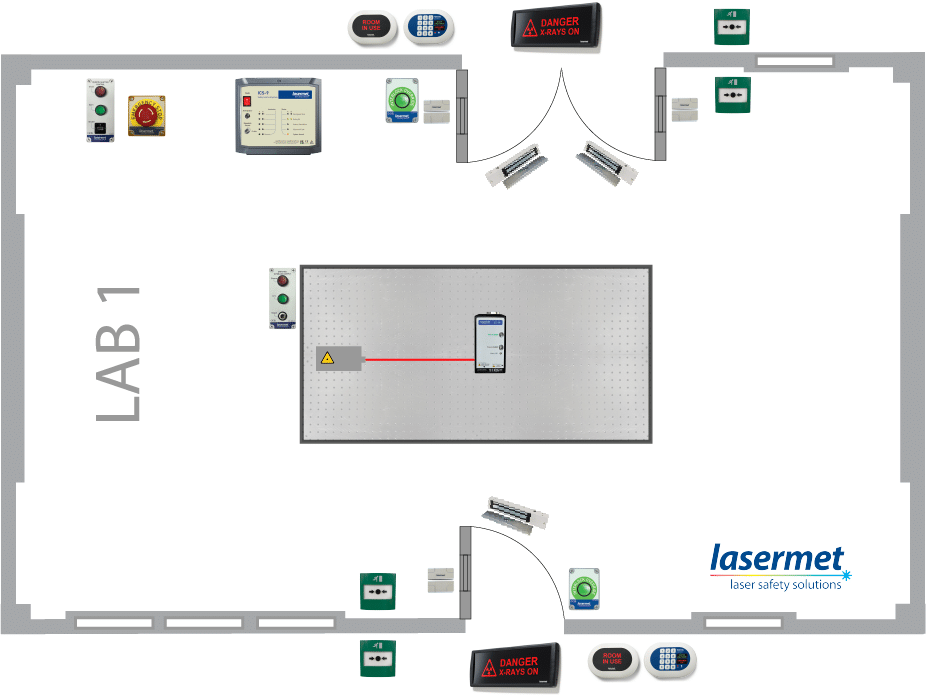

How a Standard Interlock System Works

Above is an example of a standard laser interlock system installed in a lab. The lab has two entry points, a double door and a single door, and an optical table set-up with a laser. Warning signs with dual messages “No Hazard Laser Off” and “Danger Laser On” are strategically placed at the entry points. Lasermet’s interlock system provides a comprehensive solution to safety with interlocked doors, tables, emergency stops, and override procedures in place.

In a Class 4 laser lab, the Lasermet interlock system can:

- Automatically disable laser output when the door is opened.

- Require door closure and key switch activation before enabling the laser.

- Integrate with emergency stops and warning signs.

- Override the door to allow entry without disabling the laser output.

- Monitor and control the status of laser beam shutters on an optical table.

- And more…

Case Studies

Read more about our solutions and how we help companies achieve their laser safety needs.

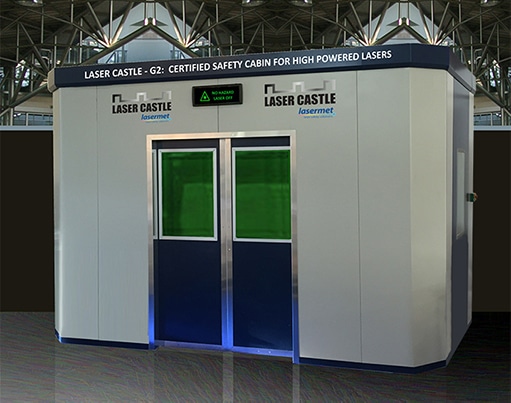

Lasermet’s Laser Castles provide laser safety for Talens personnel in their crankshaft laser hardening process in Spain

Talens Systems, (a member company of the Etxe-Tar Group based in Spain) ordered a second Laser Castle for their laser processing business and took delivery of it at the end of May 2016. Talens Systems develops Flexible Laser Heat Treat systems for the automotive industry, oil and gas, and the renewables industries.

Lasermet’s Laser Castle safely contains laser radiation during decommissioning at Sellafield

Sellafield Ltd is the legal entity responsible for Sellafield, which is owned by the Nuclear Decommissioning Authority. Sellafield has led the development of the UK’s nuclear industry, from the production of plutonium for the country’s nuclear deterrent programme through to the development of nuclear power generation.

Scientists use Lasermet’s laser blocking curtains in the Acropolis, Athens

Scientists carrying out restoration work in the Acropolis in Athens, Greece are using Lasermet‟s laser blocking curtains to set up a laser laboratory in the public area.

Scientists have set up an advanced laser laboratory in a public area of the Acropolis Museum in Greece, allowing visitors to see how the technology is being used to restore ancient sculptures to their former glory.