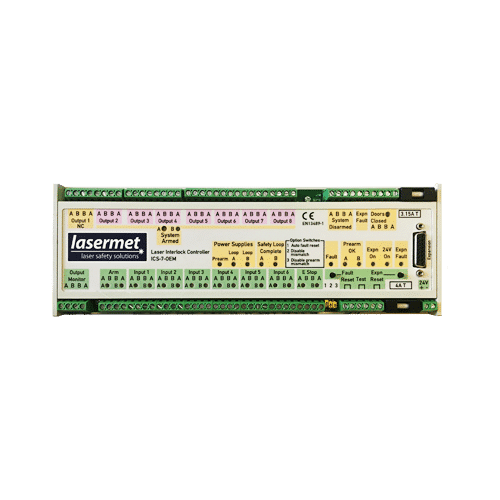

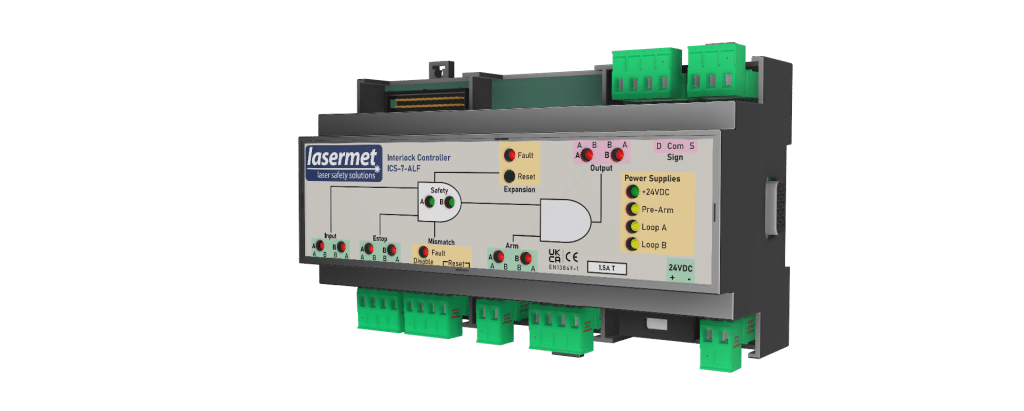

ICS-7-ALF Interlock Controller

Interlock Controller for ALF-ready Systems

The ICS-7-ALF protects personnel from hazardous laser exposure by integrating dual-channel safety control with helmet-based interlock monitoring.

It features advanced monitoring capabilities, including:

- Continuous monitoring of helmet wear and visor closure

- Dual-channel, cross-checked architecture (PL ‘e’ compliant)

- Volt-free fail-safe interlock outputs for laser and PLC control

- Seamless integration with ALF-ready equipment and expansion options

Description

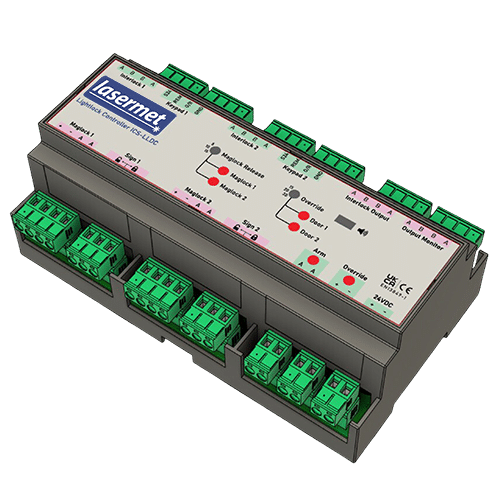

The ICS-7-ALF is a dual-channel laser safety interlock control system designed to integrate seamlessly with PLC controllers, lasers, and robotic systems. As part of a complete laser safety setup, the ICS-7-ALF ensures that the laser can only be armed when all safety interlocks—including the Passive Laser Welding Helmet—are in a safe operating condition.

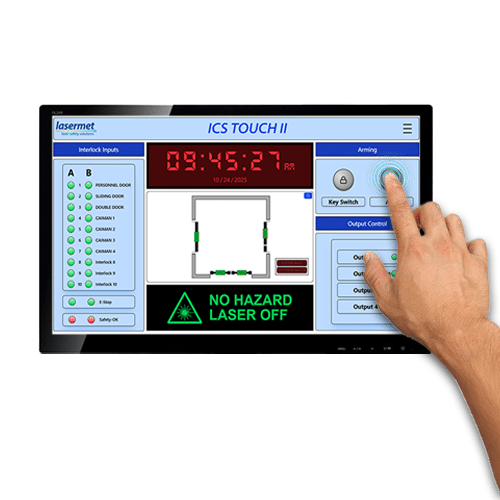

PLC Integration

Works in conjunction with existing control systems to manage laser operation based on verified safety conditions.

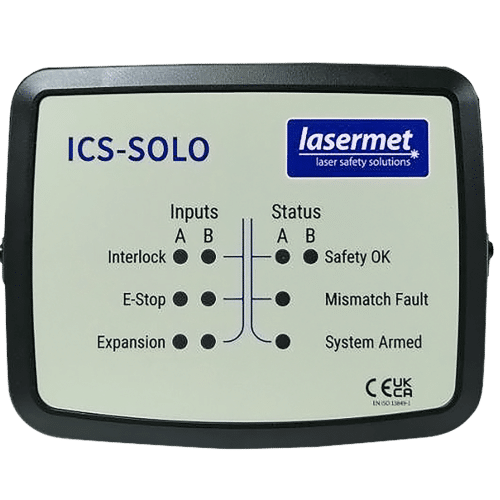

Dual-Channel Safety

Built with full dual-channel, cross-checked architecture, compliant with EN ISO 13849-1, achieving performance level ‘e’. This translates to a mean time to dangerous failure of 381 years—ensuring outstanding reliability.

Arming Control

Requires two external volt-free contacts (typically from a PLC) to arm the system. The laser is only enabled once these are closed and all interlock conditions are met.

Fail-Safe Outputs

Includes fail-safe interlock outputs rated at 4A resistive, 50VDC, for controlling laser operation, door locks, or sending signals to a PLC. All outputs are volt-free contacts and are closed when the system is armed.

Expandable Design

Features an expansion port for easy system modification or scaling.

Laser Welding Helmet Monitoring

The ICS-7-ALF continuously monitors the Passive Laser Welding Helmet, which is fitted with integrated safety interlock switches to ensure it is worn correctly before laser activation.

The system checks that the helmet is securely in place and that the visor is fully closed. If the helmet is removed, misaligned, or improperly worn, the interlock triggers and the system immediately disarms, disabling the laser output to prevent accidental exposure.

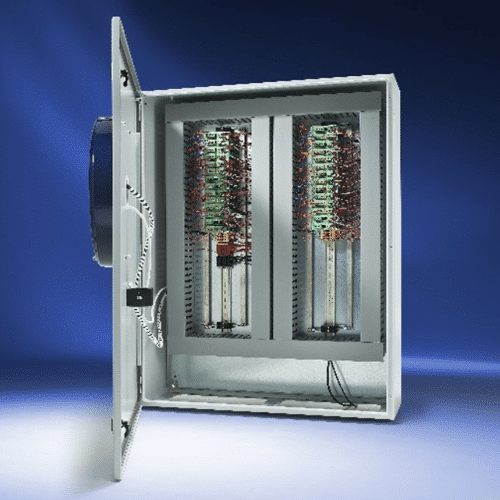

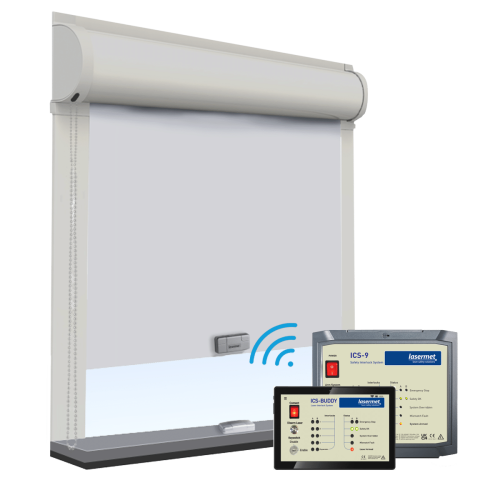

Photo on the right side is the hanging bracket that connects all necessary equipment including, mini sign, emergency stop button, and distribution boxes.

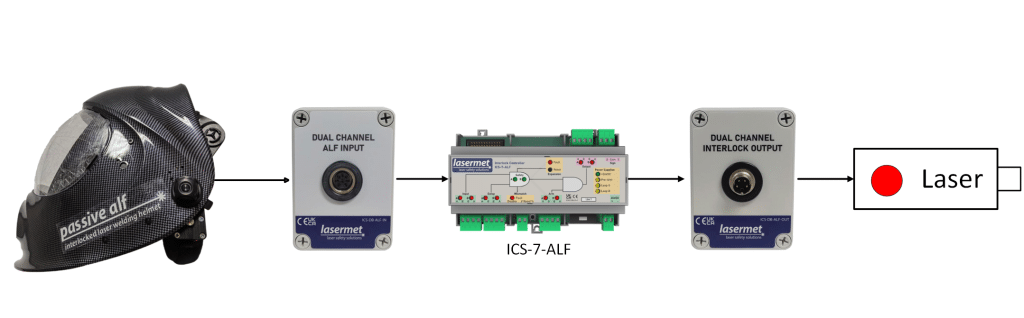

ICS-7-ALF Block Diagram

This block diagram illustrates the typical system architecture of the ICS-7-ALF interlock control system. The Passive ALF Laser Welding Helmet connects to the ALF Input Distribution Box (ICS-DB-ALF-IN), which then links to the ICS-7-ALF Controller. The controller outputs to the Interlock Output Box (ICS-DB-ALF-OUT), which finally interfaces with the laser system. This configuration ensures that the laser only activates when all interlocks are securely validated, providing a high level of operator safety.