Lasermet’s Laser Castle safely contains laser radiation during decommissioning at Sellafield

Sellafield Ltd is the legal entity responsible for Sellafield, which is owned by the Nuclear Decommissioning Authority.

Sellafield has led the development of the UK’s nuclear industry, from the production of plutonium for the country’s nuclear deterrent programme through to the development of nuclear power generation. Today it is faced with the challenge of cleaning-up the legacy of the site’s early operations, including some of the most hazardous nuclear facilities in Europe.

Sellafield is home to the oldest nuclear facilities in the UK and it is focusing its efforts on safely accelerating the clean-up of the oldest facilities.

Glovebox Size Reduction

One of challenges being overcome is to decommission gloveboxes which are contaminated with alpha emitters. The glovebox is a sealed container designed to allow manipulation of objects in a separate atmosphere.

Gloveboxes used for research, development and operations that have come to the end of their life will be decommissioned as part of the site’s clean-up programme.

Many of these are contaminated with alpha-bearing material and current decommissioning plans include manual techniques which are often hazardous and time consuming. There is a driver to address this challenge using alternative technologies to deliver safer, more efficient decommissioning at a lower cost.

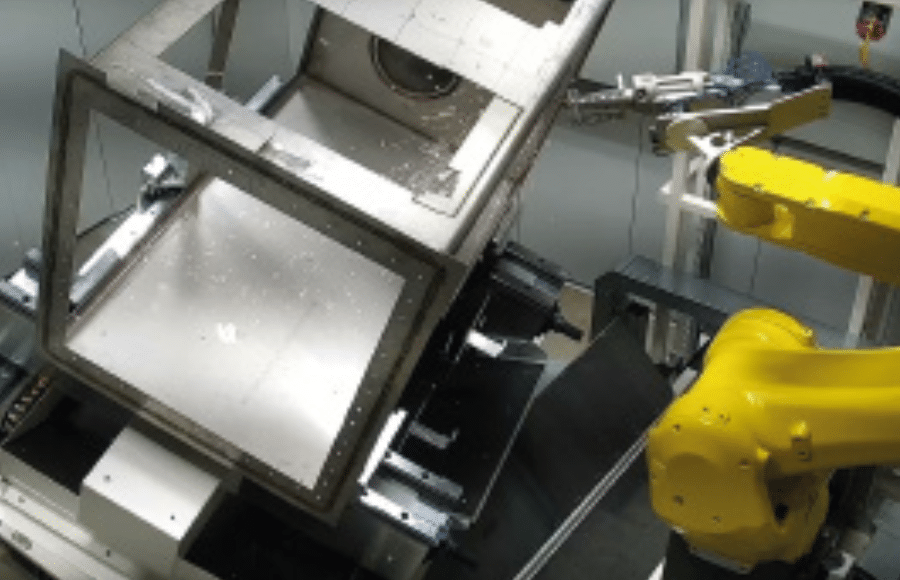

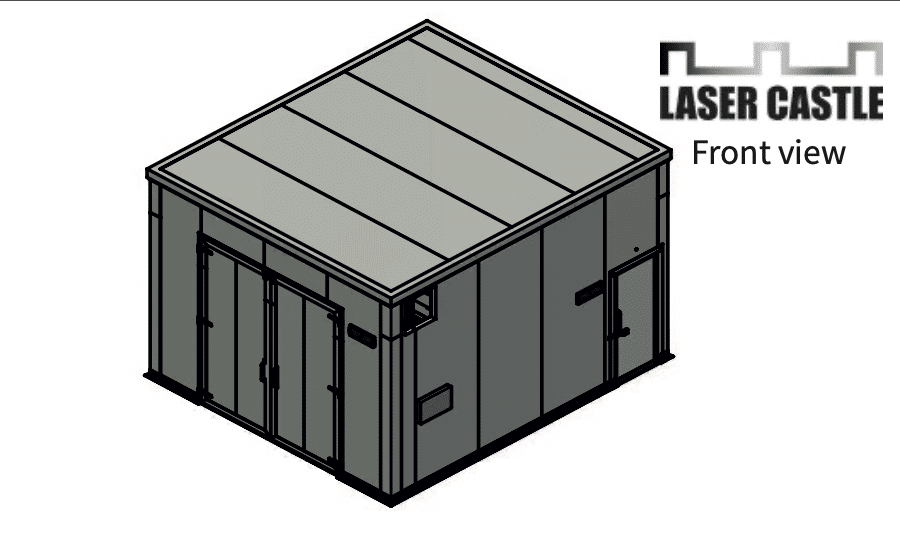

A facility for reducing the size of gloveboxes has been built in an existing laboratory on the Sellafield site. The facility is enclosed by Lasermet’s Laser Castle – laser safety enclosure. This self contained laser cutting facility will reduce the risk to operators during remote size reduction of alpha contaminated gloveboxes.

This includes a laser cutting system mounted on a six degrees of freedom robotic arm with recovery of waste and minimum human intervention all housed within the Laser Castle.

Alpha Active Demonstrator (AAD)

Inactive trials have now been completed, with active tests planned for early 2022. A phase of active demonstrations will take place in order to deliver the pre-defined learning objectives and to enable future decisions on the capability to be made.

The AAD project will determine whether to scale up and build a Central Breakdown Facility or whether another Engineered Drum Store or Waste Treatment Complex is required to house additional waste from the decommissioning of alpha contaminated gloveboxes.

Laser Containment with Laser Castle

To decommission the contaminated gloveboxes, they need to have their volume reduced. This is done using a laser cutting, multi-axis robot which is securely installed within a laser safety enclosure. The enclosure prevents the escape of any laser radiation while the laser cutting process is underway.

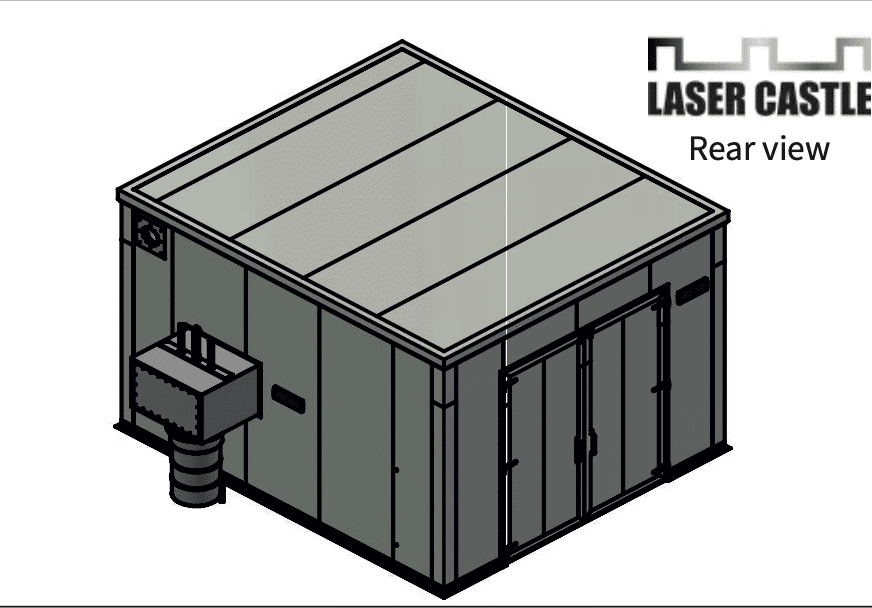

This enclosure, called the Laser CastleTM, which is the size of a large room, prevents laser radiation from escaping and causing injury while the laser is active. The Laser Castle is a modular-build laser safety enclosure that can withstand multi-kW laser radiation and remain intact.

Active Guarding

To increase the safety measures even further, Lasermet has installed an additional safety mechanism called the Laser Jailer®.

This is an active laser guarding system that covers the complete inside of the enclosure including the doors, the walls and the roof. Its function is to isolate the laser safety input to stop the emission of laser radiation within 50ms if the beam should inadvertently strike any of the internal surfaces. It does this by using a Laser Interlock® Controller that continuously monitors the circuits installed around the internal surfaces. Using Laser Jailer prevents the escape of laser radiation from the cabin and stops the laser cutter beam from causing further damage to the enclosure.