In industries where precision and safety are paramount—such as laser technology, medical devices, and electronics— the reliability of a test report can make or break regulatory compliance. When it comes to lasers, even a small oversight can have serious consequences. That’s where UKAS-accredited test houses come in. Let’s dive into how UKAS (United Kingdom Accreditation Service) accredits these labs, how they are structured, and what makes Lasermet standout in this highly specialised field.

What is UKAS?

UKAS is the national body appointed by the UK government to accredit organisations providing testing, certification, and calibration services.

When a test house earns UKAS accreditation, it means that the lab is not only technically competent but also meets internationally recognised standards such as IS0/IEC 17025:2017 for testing and calibration labs. UKAS works closely with the Department for Business and Trade (DBT) to maintain high standards of quality across industries.

What are Test Houses?

A test house, or testing laboratory, is a specialised facility that performs tests on products, materials, or systems to ensure they meet industry standards. Depending on their specialisation, test houses might focus on areas like:

These test houses issue reports or certificates that are essential for compliance, CE marking, or international exports. Think of them as the trusted middleman between product development and market approval.

Structure of Accredited Test Houses

UKAS-accredited test houses follow a strict structure to ensure that their testing is reliable, impartial, and traceable. They operate under ISO/IEC 17025: 2017, which defines the requirements for the competence of testing labs. Here’s a closer look at what this structure entails:

1. Qualified Personnel

Every test conducted must be handled by qualified personnel. At Lasermet, the teams who work with laser products need to have a deep understanding of optical physics, laser classification, and laser safety risks. It’s not just about following procedures, it’s about applying expert knowledge to each test.

2. Defined Scope of Accreditation

Each accredited test house maintains a formal scope of the standards and methods it’s qualified to perform. Lasermet’s UKAS-accredited scope includes laser product testing to BS EN 60825‑1 and LED photobiological safety testing to BS EN/IEC 62471 including full compliance documentation.

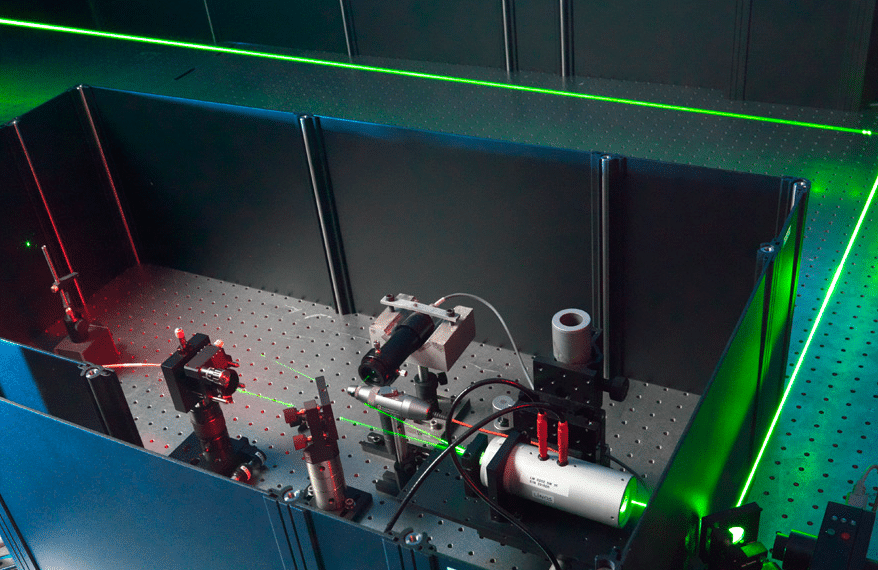

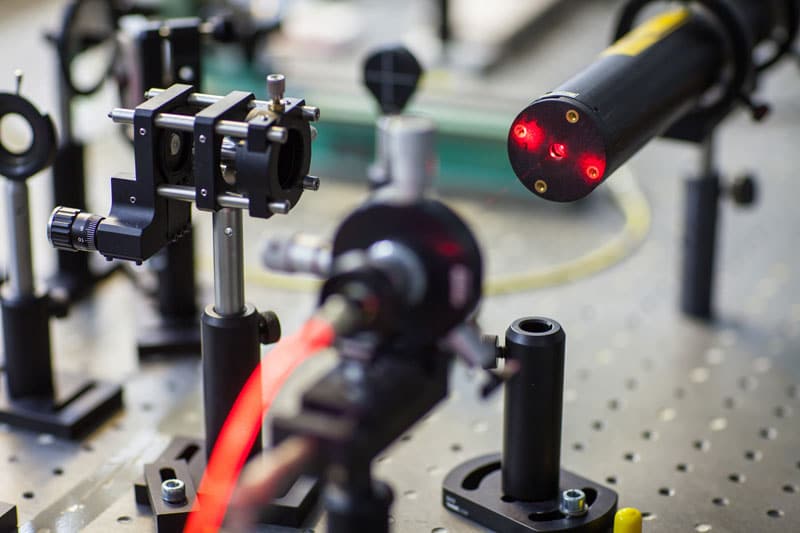

3. Controlled Environment and Facilities

Test houses must maintain a controlled setting to ensure safe and accurate testing. Lasermet’s testing lab facility in the UK is UKAS-accredited, one of the few test houses in the country that test to BS EN 60825-1 and BS EN/IEC 62471.

4. Calibrated and Traceable Equipment

Test equipment—like power meters or beam profilers—must be regularly calibrated and traceable to national standards. These measurements ensure compliance with European and International standards.

5. Documented Test Procedures

Each test follows a standard operating procedure (SOP) that aligns with specific testing methods, such as the requirements set in BS EN/IEC 60825-1 for laser classification.

Lasermet will check the documentation and labeling of a laser to ensure the proper warnings and classification labels are in place, according to international standards.

6. Data Recording and Quality Assurance

Test houses also implement strict quality control measures to ensure results are accurate and reliable. This could include:

- Internal audits to assess testing processes

- Repeatability studies to confirm that results can be replicated

- Blind sample tests to detect potential bias or equipment malfunction

Example of Products Tested in Accredited Test Houses

| Product Type | Standard Tested Against | Example Test Performed |

|---|---|---|

| Laser Pointer (Class 2) | IEC 60825-1 | Output power, divergence, labelling checks |

| Surgical Diode Laser | IEC 60601-2-22, IEC 60825-1 | Emission stability, wavelength checks, interlock system testing |

| LED Dental Curing Lamp | IEC 62471 | Blue light hazard, irradiance measurement |

| Industrial Fibre Laser | IEC 60825-1, 21 CFR 1040.10 | AEL limits, beam containment, remote control operation verification |

| Laser Enclosure System | Custom (Functional Safety) | Interlock validation, system failure response time |

UKAS Accreditation Process

How does a test house become UKAS-accredited? It’s a thorough process involving the accreditation bodies.

1. Application Submission

Test houses submit an application outlining the scope of accreditation including the standards they wish to test against. The application includes details about facilities, equipment, staff qualifications, and testing procedures.

2. Preliminary Assessment

UKAS conducts a preliminary review to check the test house’s readiness. They evaluate the infrastructure, procedures, and quality management systems of the organisation.

3. Formal Assessment

UKAS auditors perform an on-site evaluation of the lab. They inspect staff adherence to procedures, test equipment, and overall compliance with health and safety standards.

4. Technical Review

Subject-matter experts confirm the lab’s competence in carrying out the tests. The review ensures equipment, methods, and staff qualifications align with accreditation standards.

5. Accreditation Grant

If successful, UKAS issues an Accreditation Certificate and a Schedule of Accreditation listing the accredited tests. Accreditation is typically valid for 4 years.

6. Surveillance & Re-assessment

UKAS conducts periodic surveillance visits (every 12-18 months) to ensure continued compliance. This includes checking operations, equipment calibration, and audit of test reports.

Re-accreditation of Test Houses

After 4 years, the test house undergoes a full reassessment to maintain accreditation. Organisations must submit updated documents and undergo another full evaluation to ensure continued compliance.

Lasermet on Spotlight

Lasermet is the only Testing House in the UK with UKAS accreditation for LASER and LED Testing

Why UKAS Accreditation Matters

UKAS accreditation is more than a formality, it’s a mark of trust, quality, and safety. For companies in laser and LED industries, it ensures that testing is accurate, impartial, and compliant with international standards.

A UKAS-accredited test house like Lasermet delivers dependable results you and your customers can trust.

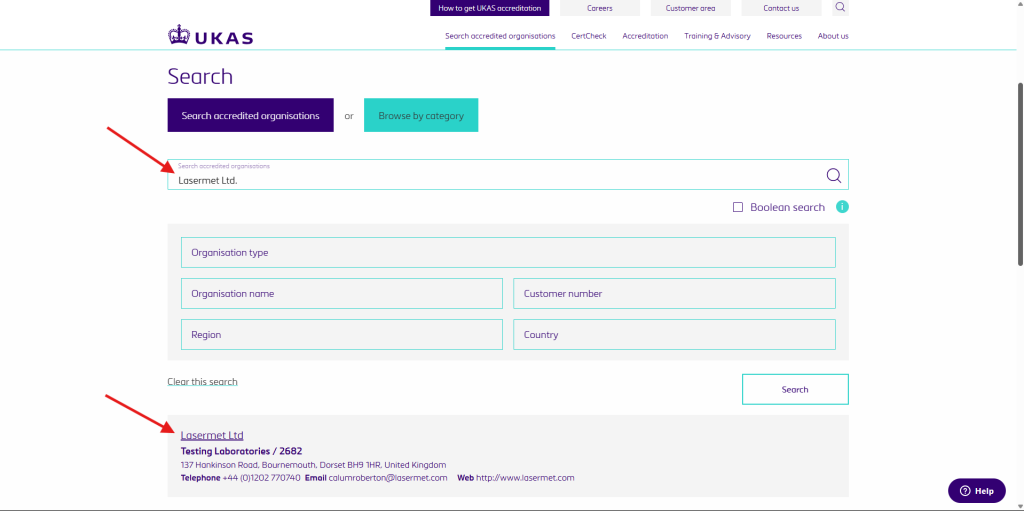

How to Find Accredited Test Houses

To find UKAS-accredited test houses, visit the UKAS Accredited Bodies Directory. You can search by:

- Test type (e.g., IEC 60825)

- Standard (e.g., IEC 60601-2-22)

- Industry sector (e.g., medical, electronics)

- Search Accredited Organisation (e.g., Lasermet Ltd.)

Results will be displayed below if the organisation is UKAS Accredited.

UKAS accreditation is more than just a certification—it’s a mark of technical excellence. For anyone developing or testing laser products, working with a UKAS-accredited test house like Lasermet ensures your compliance is backed by internationally recognised standards. Whether you’re navigating the complexities of laser safety or preparing for FDA approval, Lasermet is a trusted partner in this rigorous process.

Ready to Ensure Compliance and Quality?

Partner with Lasermet, a UKAS-accredited test house ,for expert laser and LED product testing.

Disclaimer: This article is intended for informational purposes only. While every effort has been made to ensure the accuracy of the content based on the IEC 60825-1 standard and related resources, we make no representations or warranties, express or implied, regarding the completeness, accuracy, or applicability of the information provided. This content does not constitute legal or regulatory advice. Readers are advised to consult the relevant standards documentation and seek professional guidance to ensure full compliance with applicable regulatory requirements. We disclaim any liability for decisions made or actions taken based on the information contained herein.