Lasermet’s MuLEx System provide solution to newly constructed laser lab cleanrooms

Lasermet has recently worked with one of North America’s leading contractors for environmental rooms to deliver a suite of laser safety cleanrooms for a project in Connecticut, U.S.A.

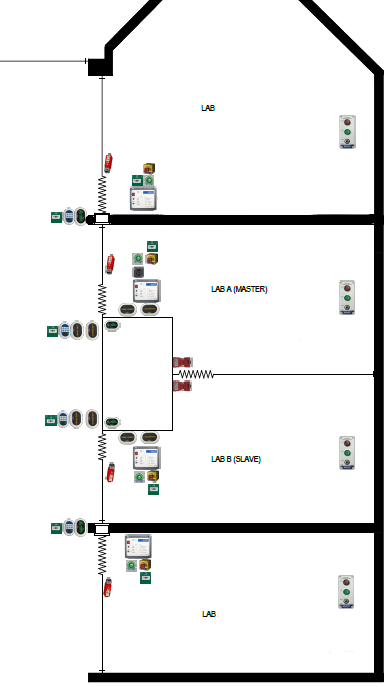

The project involved the design, install, and commissioning of a complex laser safety system for multiple cleanrooms interconnected by laser blocking curtains. Each cleanroom was provided a complete complement of laser safety interlocks including interlock controllers, interlock switches, emergency stops, dual message warning signs, and laser beam shutters.

Lasermet, with years of experience and expertise in the field of laser safety, have been proven to be the ideal choice for this venture. The MuLEx System (Multi-room Laboratory Expansion) by Lasermet is the latest in safety interlock technology when it comes to complex interconnected multiple laboratory layouts.

The Challenge

The challenge was to create a simple to use, simple to understand laser safety interlock system for a complex interconnected laser laboratory layout. The client premises consisted of a large room subdivided into smaller cleanroom areas. Each cleanroom has access via one or more laser blocking curtain which acts as an access door.

The basic requirements of the project were to have each smaller cleanroom operated as its own independent interlock system. In addition, two adjoining cleanrooms (which we can refer to as Laser Controlled Areas – LCAs) with their dividing laser curtain opened may also be operated in a combined mode where they act as a single lab.

The Lasermet Solution

The solution was to use Lasermet’s MuLEx System to implement the necessary functionality for the cleanrooms. The MuLEx has built-in logic which allows lab personnel to easily switch between a ‘Labs Separate’ and ‘Labs Joined’ mode to combine two or more adjoining labs. A dual-message sign indicates when the system has been switched to either ‘Labs Separate’ or ‘Labs Joined’ mode.

When in ‘Labs Separate’ mode each cleanroom functions as its own independent interlock system. Ideal for conducting multiple laser experiments or tests at the same time.

Lasermet’s standard interlock system installed in each cleanroom includes an ICS-9 Interlock Controller, E-stop buttons, access keypad, locking curtain door interlock switch, laser warning signs, distribution boxes and laser beam shutters.

The system must be in a safe condition in order to arm the laser. That means all entry points must be closed and all emergency stops released. When armed, the laser warning sign will display a red ‘Warning Laser On’ message and the curtain door will be locked.

A time-limited override allows personnel to enter or exit the room without tripping out / disarming the laser. Personnel must key in the correct code on the access keypad to gain entry. This prevents unauthorized access to the cleanroom.

In ‘Labs Joined’ mode, the dividing curtain must be opened and the two adjoining cleanrooms are able to be combined to create a larger cleanroom. In this mode only the main Interlock Controller will be able to arm the system, with the second one taking on the role of an extender. The same principles of the standard interlock system apply in terms of arming, safety, and override.

Lasermet Interlock Equipment

MuLEx SYSTEM

The MuLEx Multi-room Expansion is intended to simplify the implementation and operation of interlock systems when combining multiple labs. Many large laboratory layouts use laser guards or curtains to divide the area into multiple smaller rooms. The MULEX allows this splitting of rooms without sacrificing laser safety. Each smaller area has its own interlock controller but when configured as one large room with the dividers open, it is controlled by a master interlock controller.

The MULEX system can accommodate connection of up to five laser-controlled areas or interlock controllers and can be stacked along with other expansion cards for Lasermet’s Interlock Controller.

ICS-9 INTERLOCK CONTROLLER

The ICS-9 is a dual channel interlock controller achieving the highest level of safety integrity (PL‘e’ to ISO 13849-1). The safety functions operate via hard-wired dual channel circuits so that PLe safety integrity is maintained.

DOOR OVERRIDE

Lasermet’s ICS-KP23 Access Keypad with dual channel override allows users to override an associated door or global override all connected doors in an area. The keypad is situated outside a door which is electrically locked and monitored by the interlock system.

ORCA LASER BLOCKING CURTAINS

Made of Lasermet’s special laser blocking Orca material, these curtains are certified to BS EN IEC 60825-4 Safety of Laser Products Part 4 – Laser Guards.

Orca Laser Blocking Curtains are intended to be used to stop stray laser radiation from escaping a laser-controlled area such as a laboratory, operating theatre or other area containing a laser. Made-to-measure, the curtains are ideally suited to prevent inadvertent escapes of laser radiation within the PEL limits.

| Irradiated Area | PEL (T3) 10s | PEL (T2) 100s |

| 4 mm² | 3.90 MW/m² | 2.20 MW/m² |

| 2000 mm² | 0.62 MW/m² | 0.35 MW/m² |

Lasermet’s interlock system installation was the ideal solution for the client site, providing laser safety, security, and flexibility with the MuLEx system. Lab personnel can easily switch between lab modes with a flick of a switch, eliminating the need to reconfigure the whole interlock safety system.

Lasermet have successfully delivered and commissioned the project as of April 2025 at the site in Wilton, CT. With our expertise in laser safety and with hundreds of laser safety installations around the world, Lasermet continues to support leading institutions with state-of-the-art safety solutions, enabling scientific breakthroughs while ensuring the highest level of protection.