Lasermet’s Laser Castles provide Laser Safety for Talens

Lasermet’s Laser Castle provide laser safety for Talens personnel in their crankshaft laser hardening process in Spain

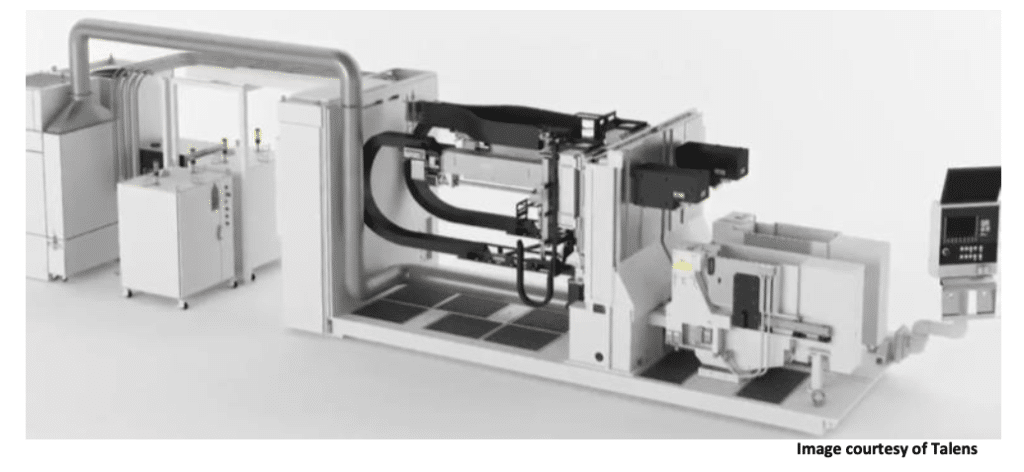

Talens Systems, (a member company of the Etxe-Tar Group based in Spain) ordered a second Laser Castle for their laser processing business and took delivery of it at the end of May 2016. Talens Systems develops Flexible Laser Heat Treat systems for the automotive industry, oil and gas, and the renewables industries.

The delivery and integration of the Laser Castle laser safety enclosure ensures the protection of personnel from dangerous laser radiation. The design, manufacture, installation, commissioning and laser safety certification of the fully interlocked enclosure was completed by the Lasermet installation team.

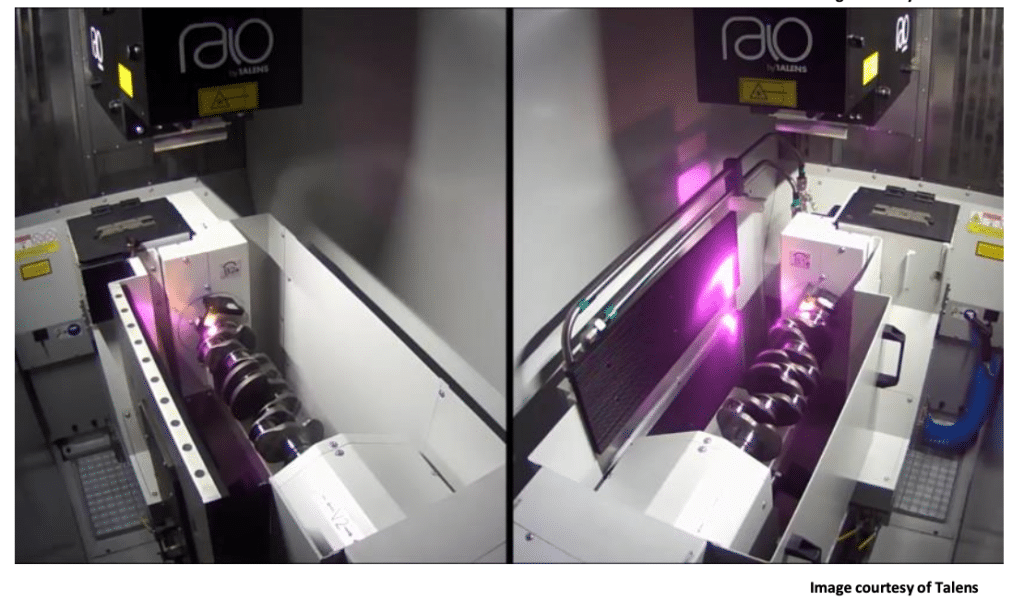

The “Laser Jailer” active laser guarding system surrounds the inside of the cabin. The connections to the active guarding panels on the back of the inside of the door can be seen.

The active guarding system is installed to prevent the escape of high power laser radiation. If a laser beam inadvertently strikes the cabin interior the laser safety interlock controller immediately switches off the laser rendering it safe.

Why Talens chose Laser Castle

Customers also have the option of including Lasermet’s “I-Extract” or the “Swallow” laser fume extraction system that can be integrated into the extraction ducting of the enclosure.

The Laser Castle is a certified laser safety enclosure designed to isolate a robot that uses a high powered, multi-kW laser of any wavelength. For example, if the laser beam strikes the enclosure wall, the energy absorbing construction prevents the escape of a multi-kW laser beam for many minutes depending on the power density.

For yet higher power densities and higher powered multi-kW lasers, Lasermet’s active guarding system can be used in addition to the passive capabilities of the Laser Castle. The Laser Jailer active guarding system – protects personnel outside the enclosure in the event of a stray laser beam-strike, by isolating the laser safety input to the laser in less than 50ms. This means that, if the laser beam strikes the inside of the enclosure wall, it is switched off virtually immediately by the ICS interlock controller.

Further options include the Glaser Jailer – the active laser filter window – which can be used as an alternative to the HD CCTV. Other options include manual, automatic or guillotine doors and rotating tables that transfer workpieces between the inside and outside of the enclosure – safely.